HEADLIGHT LEVELING ECU > INSTALLATION |

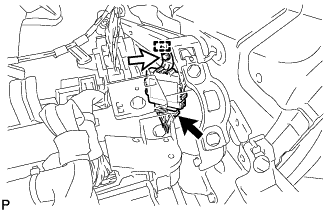

| 1. INSTALL HEADLIGHT LEVELING ECU ASSEMBLY (for LHD) |

|

Engage the guide.

Install the headlight leveling ECU assembly with the bolt.

Connect the connector.

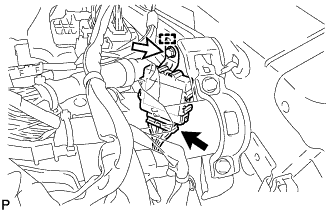

| 2. INSTALL HEADLIGHT LEVELING ECU ASSEMBLY (for RHD) |

|

Engage the guide.

Install the headlight leveling ECU assembly with the bolt.

Connect the connector.

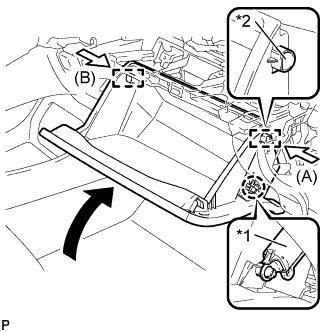

| 3. INSTALL GLOVE COMPARTMENT DOOR ASSEMBLY (for LHD) |

|

With the glove compartment door assembly opened approximately 55° from its closed position, engage the 2 hinges horizontally.

| *a | Opened Approximately 55° |

| *b | Closed |

|

Slightly bend the stoppers (A) and (B) in the directions indicated by the arrows in the illustration and engage the stoppers to install the glove compartment door assembly.

| *1 | Glove Compartment Door Stopper Sub-assembly |

| *2 | Stopper |

Engage the claw and connect the glove compartment door stopper sub-assembly.

| 4. INSTALL UPPER INSTRUMENT PANEL ASSEMBLY |

| 5. HEIGHT CONTROL SENSOR SIGNAL INITIALIZATION |

| 6. PREPARE VEHICLE FOR HEADLIGHT AIM ADJUSTMENT |

Prepare the vehicle:

|

| 7. PREPARE FOR HEADLIGHT AIMING |

|

Prepare the vehicle (except Taiwan):

|

Prepare the vehicle (for Taiwan):

Prepare a piece of thick white paper (approximately 2 m (6.6 ft.) (height) x 4 m (13.1 ft.) (width)) to use as a screen.

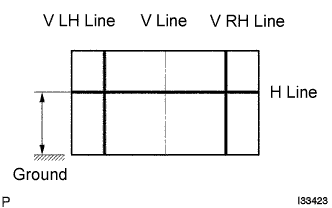

Draw a vertical line down the center of the screen (V line).

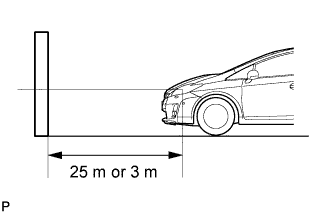

Set the screen as shown in the illustration (except Taiwan).

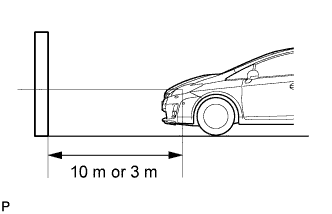

Set the screen as shown in the illustration (for Taiwan).

|

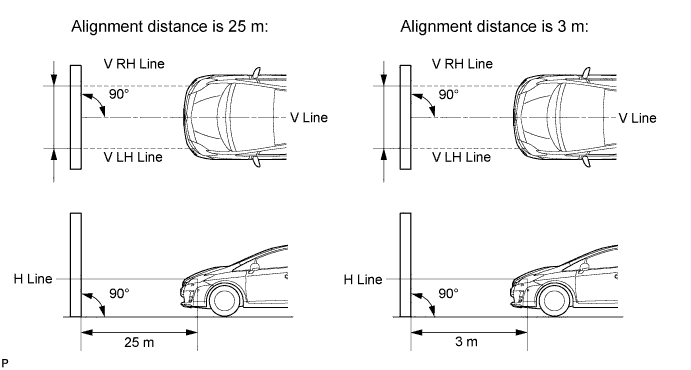

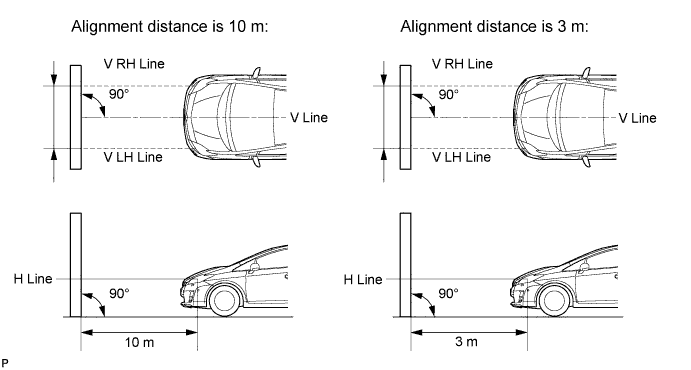

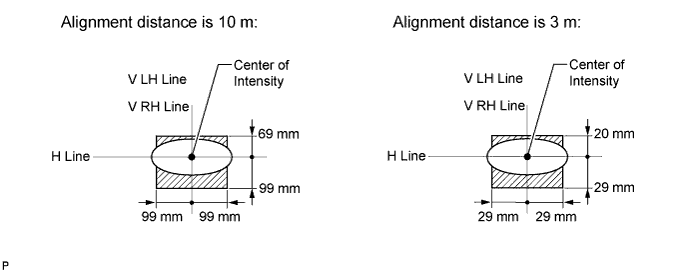

Draw base lines (H, V LH, and V RH lines) on the screen as shown in the illustration.

H Line (Headlight height):

Draw a horizontal line across the screen so that it passes through the center marks. The H line should be at the same height as the headlight bulb center marks of the low beam headlights.

V LH Line, V RH Line (Center mark position of left-hand (LH) and right-hand (RH) headlights):

Draw two vertical lines so that they intersect the H line at each center mark (aligned with the center of the low beam headlight bulbs).

| 8. INSPECT HEADLIGHT AIMING |

Cover the headlight or disconnect the connector of the headlight on the opposite side to prevent light from the headlight that is not being inspected from affecting the headlight aiming inspection.

Start the engine.

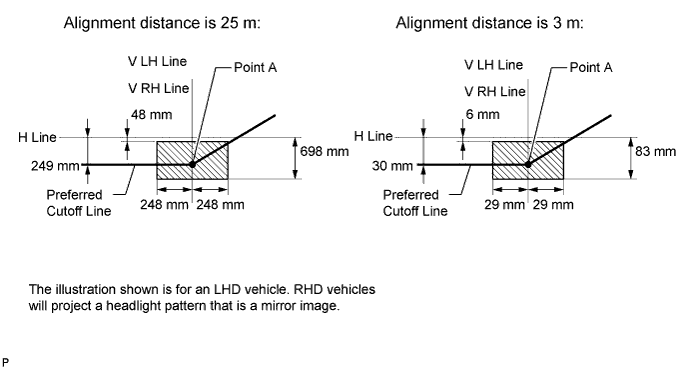

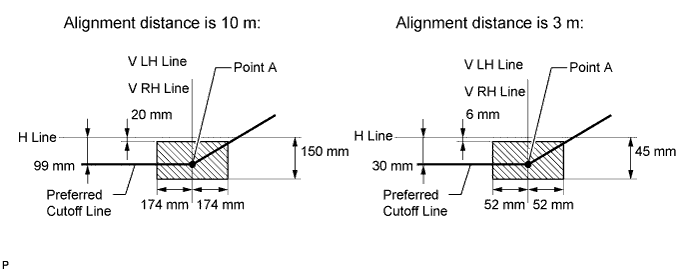

Turn on the headlights and check if the cutoff line for each low beam matches the preferred cutoff line in the illustration (except Taiwan).

Turn on the headlights and check if the cutoff line for each low beam matches the preferred cutoff line in the illustration (for Taiwan).

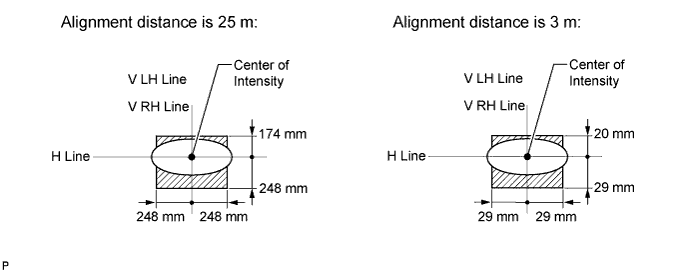

Turn on the high beams and check if the center of intensity for each high beam matches the preferred center of the intensity in the illustration (except Taiwan).

Turn on the high beams and check if the center of intensity for each high beam matches the preferred center of the intensity in the illustration (for Taiwan).

| 9. ADJUST HEADLIGHT AIMING |

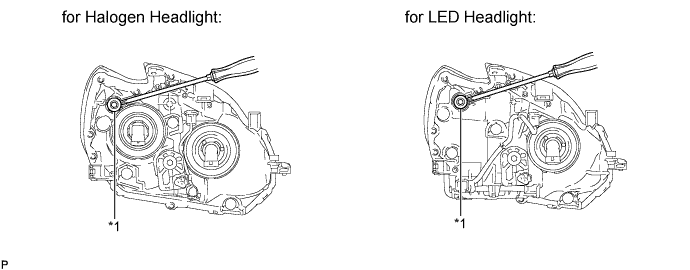

Adjust the aim vertically:

| *1 | Aiming Screw A | - | - |

Adjust the aim horizontally:

| *1 | Aiming Screw B | - | - |