ENGINE > ON-VEHICLE INSPECTION |

| 1. INSPECT COOLANT (for Engine) |

| 2. INSPECT ENGINE OIL |

| 3. INSPECT AUXILIARY BATTERY |

| 4. INSPECT AIR CLEANER FILTER ELEMENT SUB-ASSEMBLY |

Remove the air cleaner cap.

Remove the air cleaner filter element.

Visually check that the air cleaner filter element is not excessively damaged or oily.

If necessary, replace the air cleaner filter element.

Install the air cleaner filter element.

Install the air cleaner cap.

| 5. INSPECT VALVE AND ADJUSTER NOISE |

Put the engine in inspection mode (Click here).

Rev up the engine several times. Check that the engine does not emit unusual noises. If unusual noises occur, warm up the engine and idle it for over 30 minutes. Then, perform the inspection above again. If any defects or problems are found during the inspection above, perform a lash adjuster inspection (Click here).

| 6. INSPECT IGNITION TIMING |

Put the engine in inspection mode (Click here).

Warm up and stop the engine.

When using the intelligent tester:

Check the ignition timing.

Connect the intelligent tester to the DLC3.

Put the engine in inspection mode (Click here).

Turn the intelligent tester on.

Enter the following menus: Powertrain / Engine and ECT / Data List / IGN Advance.

Check that the ignition timing advances immediately when the engine speed is increased.

Enter the following menus: Powertrain / Engine and ECT / Active Test / Connect the TC and TE1 / ON.

Monitor IGN Advance of the Data List.

Enter the following menus: Connect the TC and TE1 / OFF.

Turn the power switch off.

Turn the intelligent tester off.

Disconnect the intelligent tester from the DLC3.

When not using the intelligent tester:

|

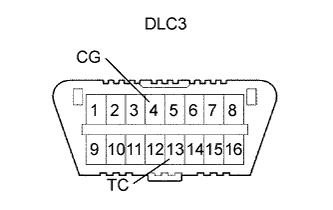

Using SST, connect terminals 13 (TC) and 4 (CG) of the DLC3.

Remove the No. 2 cylinder head cover (Click here).

|

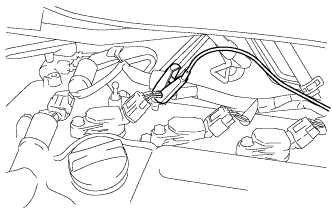

Pull out the wire harness shown in the illustration.

Connect the clip of the timing light to the wire harness.

Inspect the ignition timing at idle.

Disconnect terminals 13 (TC) and 4 (CG) of the DLC3.

Inspect the ignition timing at idle.

Confirm that the ignition timing advances when the engine rpm is increased.

Remove the timing light.

Install the No. 2 cylinder head cover (Click here).

| 7. INSPECT ENGINE IDLE SPEED |

Put the engine in inspection mode (Click here).

Warm up and stop the engine.

Connect the intelligent tester to the DLC3.

Put the engine in inspection mode (Click here).

Turn the intelligent tester on.

Enter the following menus: Powertrain / Engine and ECT / Data List / Engine Speed.

Inspect the engine idle speed.

Turn the power switch off.

Turn the intelligent tester off.

Disconnect the intelligent tester from the DLC3.

| 8. INSPECT COMPRESSION |

Put the engine in inspection mode (Click here).

Warm up and stop the engine.

Remove the 4 spark plugs (Click here).

|

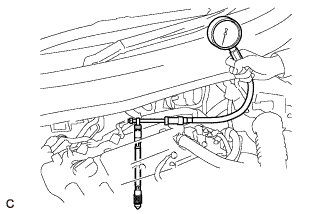

Inspect the cylinder compression pressure.

Insert a compression gauge into the spark plug hole.

Connect the intelligent tester to the DLC3.

Turn the power switch on (IG).

Turn the intelligent tester on.

Enter the following menus: Powertrain / Hybrid Control / Active Test / Compression Test / ON.

Fully depress the acceleration pedal.

Depress and hold the brake pedal, and turn the power switch on (READY).

If the cylinder compression is low, pour a small amount of engine oil into the cylinder through the spark plug hole, then inspect it again.

Install the 4 spark plugs (Click here).

| 9. INSPECT CO/HC |

Put the engine in inspection mode (Click here).

Warm up the engine.

Run the engine at 2500 rpm for approximately 180 seconds.

Insert a CO/HC meter testing probe at least 40 cm (1.3 ft.) into the tailpipe while idling.

Check the CO/HC concentration while idling and when the engine is running at 2500 rpm.

Check the DTCs (Click here).

See the table below for possible causes, then inspect the applicable parts and repair them if necessary.

| CO | HC | Problem | Possible Cause |

| Normal | High | Rough idle |

|

| Low | High | Rough idle (Fluctuating HC reading) |

|

| High | High | Rough idle (Black smoke from exhaust) |

|