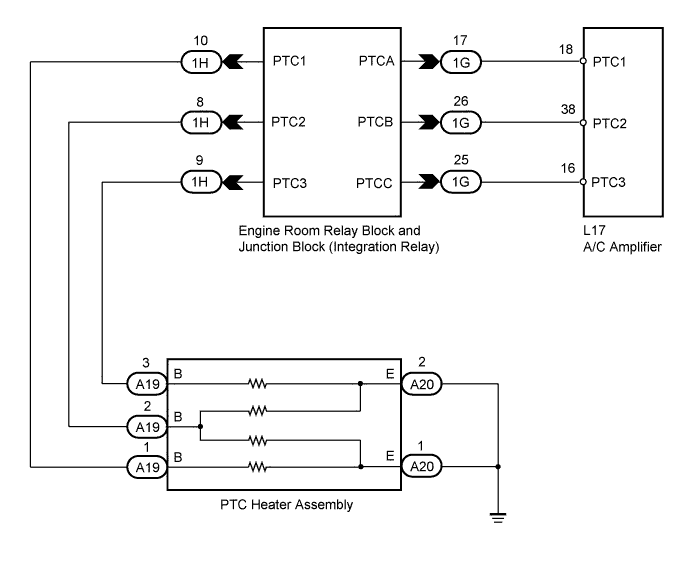

AIR CONDITIONING SYSTEM > PTC Heater Circuit |

| 1.INSPECT PTC HEATER ASSEMBLY |

|

Remove the PTC heater assembly.

Measure the resistance according to the value(s) in the table below.

| Tester Connection | Condition | Specified Condition |

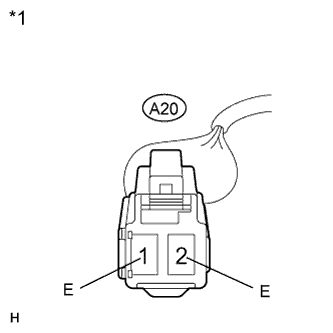

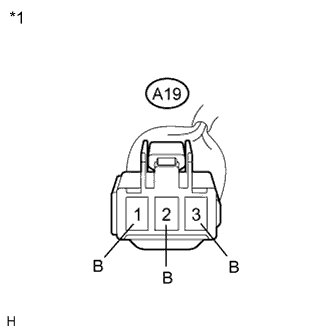

| A19-1 (B) - A20-1 (E) | Always | Below 1 Ω |

| A19-2 (B) - A20-2 (E) | Always | Below 1 Ω |

| A19-2 (B) - A20-1 (E) | Always | Below 1 Ω |

| A19-3 (B) - A20-2 (E) | Always | Below 1 Ω |

| *1 | Component without harness connected (PTC Heater Assembly) |

|

| ||||

| OK | |

| 2.CHECK HARNESS AND CONNECTOR (PTC HEATER ASSEMBLY - BODY GROUND) |

|

Measure the resistance according to the value(s) in the table below.

| Tester Connection | Condition | Specified Condition |

| A20-1 (E) - Body ground | Always | Below 1 Ω |

| A20-2 (E) - Body ground | Always | Below 1 Ω |

| *1 | Front view of wire harness connector (to PTC Heater Assembly) |

|

| ||||

| OK | |

| 3.CHECK HARNESS AND CONNECTOR (PTC HEATER ASSEMBLY - INTEGRATION RELAY) |

|

Disconnect the PTC heater assembly connector.

|

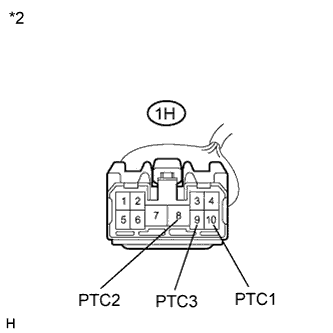

Disconnect the engine room relay block and junction block (integration relay) connector.

Measure the resistance according to the value(s) in the table below.

| Tester Connection | Condition | Specified Condition |

| A19-1 (B) - 1H-10 (PTC1) | Always | Below 1 Ω |

| A19-2 (B) - 1H-8 (PTC2) | Always | Below 1 Ω |

| A19-3 (B) - 1H-9 (PTC3) | Always | Below 1 Ω |

| A19-1 (B) - Body ground | Always | 10 kΩ or higher |

| A19-2 (B) - Body ground | Always | 10 kΩ or higher |

| A19-3 (B) - Body ground | Always | 10 kΩ or higher |

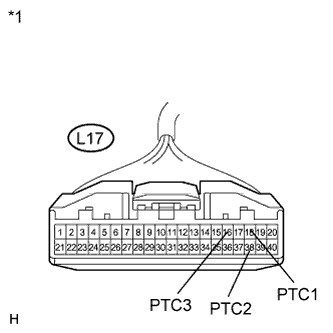

| *1 | Front view of wire harness connector (to PTC Heater Assembly) |

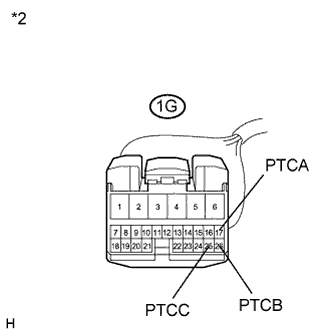

| *2 | Front view of wire harness connector (to Engine Room Relay Block and Junction Block (Integration Relay)) |

|

| ||||

| OK | |

| 4.CHECK HARNESS AND CONNECTOR (A/C AMPLIFIER - INTEGRATION RELAY) |

|

Disconnect the A/C amplifier connector.

|

Disconnect the engine room relay block and junction block (integration relay) connector.

Measure the resistance according to the value(s) in the table below.

| Tester Connection | Condition | Specified Condition |

| L17-18 (PTC1) - 1G-17 (PTCA) | Always | Below 1 Ω |

| L17-38 (PTC2) - 1G-26 (PTCB) | Always | Below 1 Ω |

| L17-16 (PTC3) - 1G-25 (PTCC) | Always | Below 1 Ω |

| L17-18 (PTC1) - Body ground | Always | 10 kΩ or higher |

| L17-38 (PTC2) - Body ground | Always | 10 kΩ or higher |

| L17-16 (PTC3) - Body ground | Always | 10 kΩ or higher |

| *1 | Front view of wire harness connector (to A/C Amplifier) |

| *2 | Front view of wire harness connector (to Engine Room Relay Block and Junction Block (Integration Relay)) |

|

| ||||

| OK | |

| 5.REPLACE INTEGRATION NO.1 RELAY |

Replace the integration relay (Click here).

Check if the same problem occurs again.

|

| ||||

| OK | ||

| ||