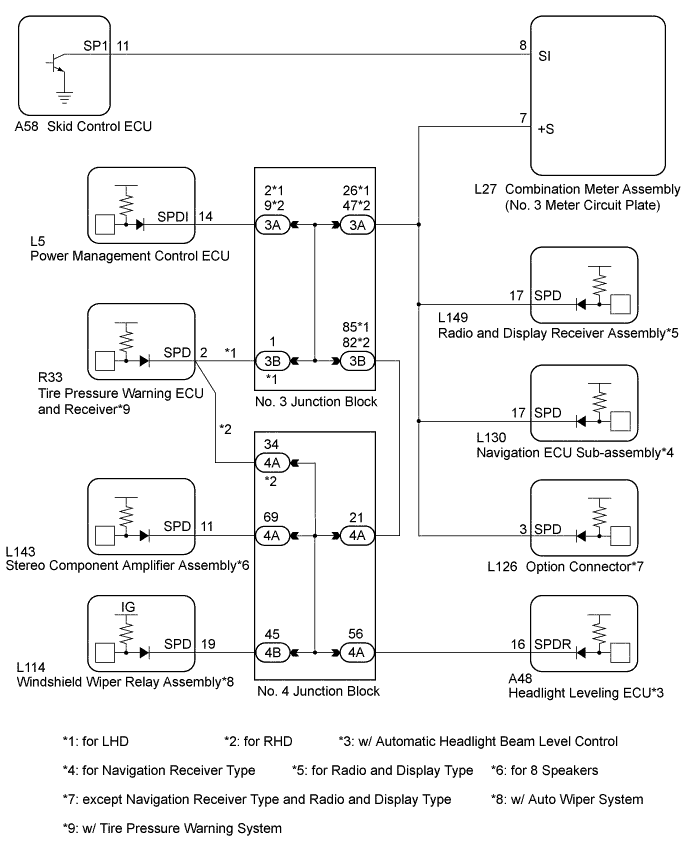

METER / GAUGE SYSTEM > Speed Signal Circuit |

| 1.INSPECT ECU TERMINAL VOLTAGE (INPUT VOLTAGE) |

|

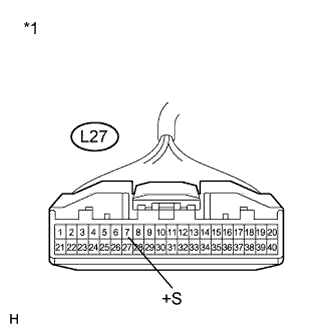

Disconnect the L27 connector.

Measure the voltage according to the value(s) in the table below.

| Tester Connection | Condition | Specified Condition |

| L27-7 (+S) - Body ground | Power switch on (IG) | 4.5 to 14 V |

| *1 | Front view of wire harness connector (to Combination Meter Assembly) |

|

| ||||

| OK | |

| 2.INSPECT COMBINATION METER ASSEMBLY (NO. 3 METER CIRCUIT PLATE) (OUTPUT VOLTAGE) |

Reconnect the L27 connector.

|

Disconnect the A58 connector.

Measure the voltage according to the value(s) in the table below.

| Tester Connection | Condition | Specified Condition |

| A58-11 (SP1) - Body ground | Power switch on (IG) | 11 to 14 V |

| *1 | Front view of wire harness connector (to Skid Control ECU) |

|

| ||||

| OK | |

| 3.INSPECT SKID CONTROL ECU (INPUT WAVEFORM) |

|

Check the input waveform.

Reconnect the A58 connector.

Remove the combination meter assembly with the connector(s) still connected.

Connect an oscilloscope to terminal L27-8 (SI) and body ground.

Turn the power switch on (IG).

Turn the wheel slowly.

Check the signal waveform according to the condition(s) in the table below.

| Item | Condition |

| Tool setting | 5 V/DIV., 20 ms./DIV. |

| Vehicle condition | Power switch on (IG), wheel being rotated |

| *1 | Component with harness connected (Combination Meter Assembly) |

| Result | Proceed to |

| OK | A |

| NG (for LHD) | B |

| NG (for RHD) | C |

|

| ||||

|

| ||||

| A | ||

| ||

| 4.CHECK HARNESS AND CONNECTOR (NO. 3 METER CIRCUIT PLATE - SKID CONTROL ECU) |

Disconnect the L27 and A58 connectors.

Measure the resistance according to the value(s) in the table below.

| Tester Connection | Condition | Specified Condition |

| A58-11 (SP1) - L27-8 (SI) | Always | Below 1 Ω |

| A58-11 (SP1) - Body ground | Always | 10 kΩ or higher |

|

| ||||

| OK | ||

| ||

| 5.CHECK HARNESS AND CONNECTOR (NO. 3 METER CIRCUIT PLATE - RADIO AND DISPLAY RECEIVER ASSEMBLY, NAVIGATION ECU SUB-ASSEMBLY) |

Disconnect the L27, 3A and L149*1, L130*2 or L126*3 connectors.

Measure the resistance according to the value(s) in the table below.

| Tester Connection | Condition | Specified Condition |

| L149-17 (SPD)*1 - L27-7 (+S) | Always | Below 1 Ω |

| L130-17 (SPD)*2 - L27-7 (+S) | Always | Below 1 Ω |

| L126-3 (SPD)*3 - L27-7 (+S) | Always | Below 1 Ω |

| L27-7 (+S) - Body ground | Always | 10 kΩ or higher |

|

| ||||

| OK | |

| 6.INSPECT RADIO AND DISPLAY RECEIVER ASSEMBLY, NAVIGATION ECU SUB-ASSEMBLY (OUTPUT VOLTAGE) |

Reconnect the L149*1, L130*2 or L126*3 connector.

Measure the voltage according to the value(s) in the table below.

| Tester Connection | Condition | Specified Condition |

| L149-17 (SPD)*1 - Body ground | Power switch on (IG) | 4 to 14 V |

| L130-17 (SPD)*2 - Body ground | Power switch on (IG) | 4 to 14 V |

| Result | Proceed to |

| OK | A |

| NG (for Radio and Display Type) | B |

| NG (for Navigation Receiver Type) | C |

|

| ||||

|

| ||||

| A | |

| 7.CHECK HARNESS AND CONNECTOR (COMBINATION METER ASSEMBLY - NO. 3 JUNCTION BLOCK) |

Measure the resistance according to the value(s) in the table below.

| Tester Connection | Condition | Specified Condition |

| L27-7 (+S) - 3A-26*1 | Always | Below 1 Ω |

| L27-7 (+S) - 3A-47*2 | Always | Below 1 Ω |

| L27-7 (+S) - Body ground | Always | 10 kΩ or higher |

|

| ||||

| OK | |

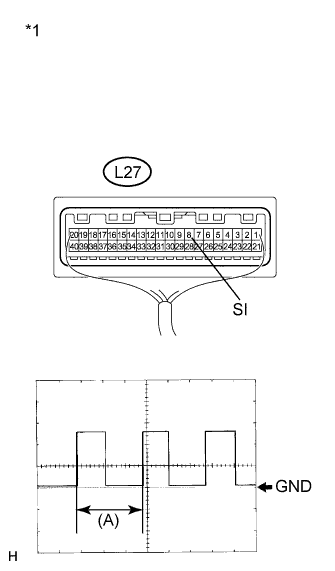

| 8.CHECK HARNESS AND CONNECTOR (NO. 3 JUNCTION BLOCK (INSTRUMENT PANEL WIRE)) |

Inspect for a short in the circuit that is connected to the junction block connector shown in the wiring diagram.

Disconnect the 3B connector.

Measure the voltage according to the value(s) in the table below.

| Tester Connection | Condition | Specified Condition |

| 3A-2*1 - Body ground | Power switch on (IG) | 4.5 to 14 V |

| 3A-9*2 - Body ground | Power switch on (IG) | 4.5 to 14 V |

| 3B-1 - Body ground | Power switch on (IG) | 4.5 to 14 V |

| 3B-85*1 - Body ground | Power switch on (IG) | 4.5 to 14 V |

| 3B-82*2 - Body ground | Power switch on (IG) | 4.5 to 14 V |

| *1 | Front view of wire harness connector (to No. 3 Junction Block) | - | - |

| Result | Proceed to |

| Voltage is not present in one circuit. | A |

| Voltage is present in all the circuits. | B |

|

| ||||

| A | |

| 9.CHECK HARNESS AND CONNECTOR (NO. 3 JUNCTION BLOCK - NO. 4 JUNCTION BLOCK) |

Disconnect the 4A connector.

Measure the resistance according to the value(s) in the table below.

| Tester Connection | Condition | Specified Condition |

| 3B-85*1 - 4A-21 | Always | Below 1 Ω |

| 3B-82*2 - 4A-21 | Always | Below 1 Ω |

| 3B-85 - Body ground | Always | 10 kΩ or higher |

|

| ||||

| OK | |

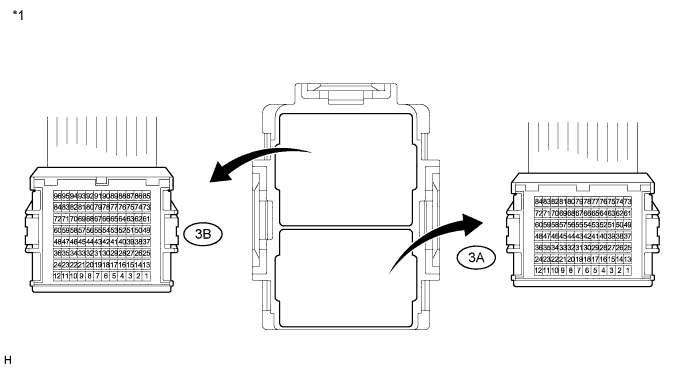

| 10.CHECK HARNESS AND CONNECTOR (NO. 4 JUNCTION BLOCK (INSTRUMENT PANEL WIRE)) |

Inspect for a short in the circuit that is connected to the junction block connector shown in the wiring diagram.

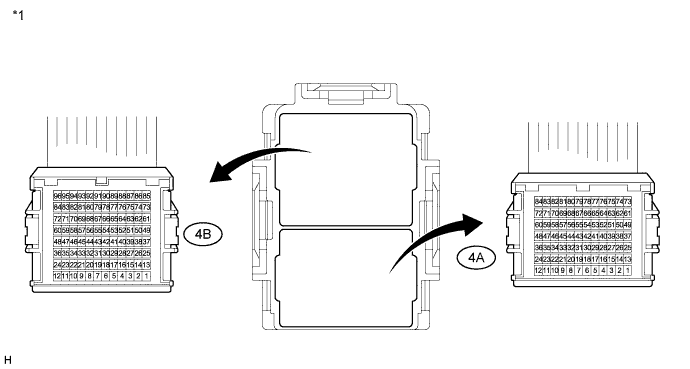

Disconnect the 4B connector.

Measure the voltage according to the value(s) in the table below.

| Tester Connection | Condition | Specified Condition |

| 4A-34 - Body ground | Power switch on (IG) | 4.5 to 14 V |

| 4A-56 - Body ground | Power switch on (IG) | 4.5 to 14 V |

| 4A-69 - Body ground | Power switch on (IG) | 4.5 to 14 V |

| 4B-45 - Body ground | Power switch on (IG) | 4.5 to 14 V |

| *1 | Front view of wire harness connector (to No. 4 Junction Block) | - | - |

| Result | Proceed to |

| Voltage is not present in one circuit. | A |

| Voltage is present in all the circuits. | B |

|

| ||||

| A | |

| 11.SYSTEM CHECK |

Select the circuit for which voltage was not present in step 8 or 10.

| Tester Connection | System that Uses the Circuit | Proceed to |

| 3A-2*1 - Body ground | Entry and Start System | A |

| 3A-9*2 - Body ground | ||

| 4B-45*3 - Body ground | Wiper and Washer System | B |

| 4A-69*4 - Body ground | Navigation System | C |

| 4A-56*5 - Body ground | Lighting System | D |

| 3B-1*1, *6 - Body ground | Tire Pressure Warning System | E |

| 4A-34*2, *6 - Body ground |

|

| ||||

|

| ||||

|

| ||||

|

| ||||

| A | |

| 12.CHECK HARNESS AND CONNECTOR (POWER MANAGEMENT CONTROL ECU CIRCUIT) |

Disconnect the L5 connector.

Measure the resistance according to the value(s) in the table below.

| Tester Connection | Condition | Specified Condition |

| L5-14 (SPDI) - Body ground | Always | 10 kΩ or higher |

|

| ||||

| OK | ||

| ||

| 13.CHECK HARNESS AND CONNECTOR (WINDSHIELD WIPER RELAY ASSEMBLY CIRCUIT) |

Disconnect the L114 connector.

Measure the resistance according to the value(s) in the table below.

| Tester Connection | Condition | Specified Condition |

| L114-19 (SPD) - Body ground | Always | 10 kΩ or higher |

|

| ||||

| OK | ||

| ||

| 14.CHECK HARNESS AND CONNECTOR (STEREO COMPONENT AMPLIFIER ASSEMBLY CIRCUIT) |

Disconnect the L143 connector.

Measure the resistance according to the value(s) in the table below.

| Tester Connection | Condition | Specified Condition |

| L143-11 (SPD) - Body ground | Always | 10 kΩ or higher |

|

| ||||

| OK | ||

| ||

| 15.CHECK HARNESS AND CONNECTOR (HEADLIGHT LEVELING ECU CIRCUIT) |

Disconnect the A48 connector.

Measure the resistance according to the value(s) in the table below.

| Tester Connection | Condition | Specified Condition |

| A48-16 (SPDR) - Body ground | Always | 10 kΩ or higher |

|

| ||||

| OK | ||

| ||

| 16.CHECK HARNESS AND CONNECTOR (TIRE PRESSURE WARNING ECU AND RECEIVER CIRCUIT) |

Disconnect the R33 connector.

Measure the resistance according to the value(s) in the table below.

| Tester Connection | Condition | Specified Condition |

| R33-2 (SPD) - Body ground | Always | 10 kΩ or higher |

|

| ||||

| OK | ||

| ||