CAMSHAFT > INSTALLATION |

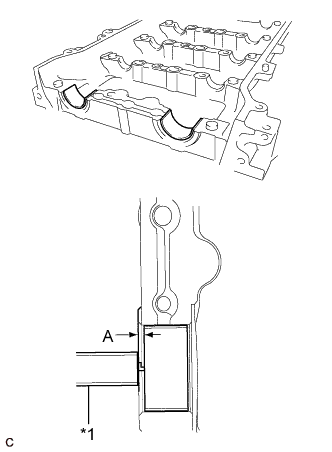

| 1. INSTALL NO. 1 CAMSHAFT BEARING |

Clean both surfaces of the bearings.

Install the 2 No. 1 camshaft bearings.

|

Using a vernier caliper, measure the distance between the bearing cap edge and the camshaft bearing edge.

| *1 | Vernier Caliper |

| 2. INSTALL NO. 2 CAMSHAFT BEARING |

Clean both surfaces of the bearings.

Install the 2 No. 2 camshaft bearings.

|

Using a vernier caliper, measure the distance between the bearing cap edge and the camshaft bearing edge.

| *1 | Vernier Caliper |

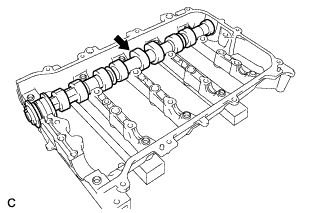

| 3. INSTALL NO. 2 CAMSHAFT |

Clean the camshaft journals.

Apply a light coat of engine oil to the camshaft journals, camshaft housings and bearing caps.

|

Install the No. 2 camshaft to the camshaft housing.

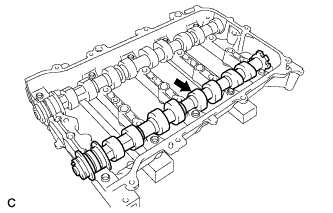

| 4. INSTALL CAMSHAFT |

Clean the camshaft journals.

Apply a light coat of engine oil to the camshaft journals, camshaft housings and bearing caps.

|

Install the camshaft to the camshaft housing.

| 5. INSTALL BEARING CAP |

Apply engine oil to the camshaft journals, camshaft housings and bearing caps.

|

Make sure of the marks and numbers on the camshaft bearing caps and place them in each proper position and direction.

| *1 | Knock Pin |

| *2 | Camshaft |

|

Tighten the 10 bolts in the order shown in the illustration.

| 6. INSTALL CAMSHAFT HOUSING SUB-ASSEMBLY |

|

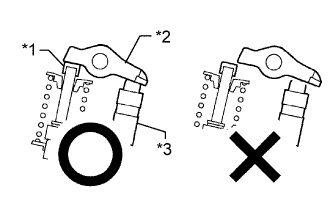

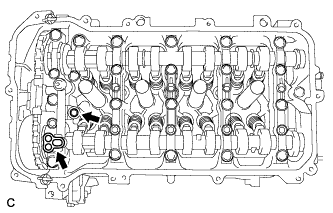

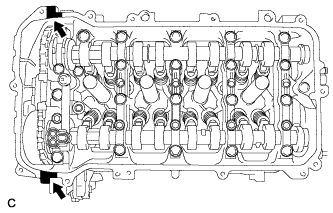

Check that the valve rocker arms are installed as shown in the illustration.

| *1 | Valve Stem Cap |

| *2 | Valve Rocker Arm |

| *3 | Valve Lash Adjuster |

|

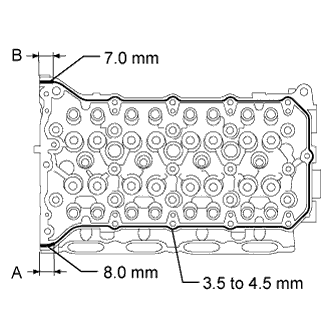

Apply seal packing in a continuous line as shown in the illustration.

| Area | Specified Condition |

| Continuous line | 3.5 to 4.5 mm (0.138 to 0.177 in.) |

| A | 8.0 mm (0.315 in.) |

| B | 7.0 mm (0.276 in.) |

|

Set the camshaft and No. 2 camshaft as shown in the illustration.

Install the camshaft housing with the 17 bolts and tighten them in the order shown in the illustration.

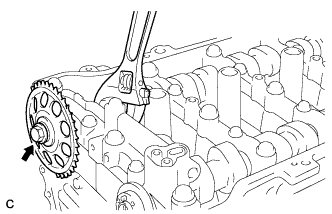

| 7. INSTALL CAMSHAFT TIMING SPROCKET |

|

Tighten the flange bolt with the camshaft timing sprocket secured in place.

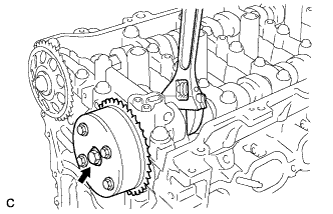

| 8. INSTALL CAMSHAFT TIMING GEAR ASSEMBLY |

|

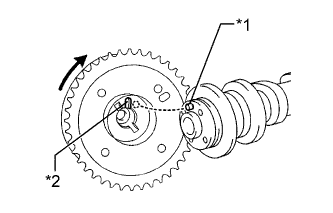

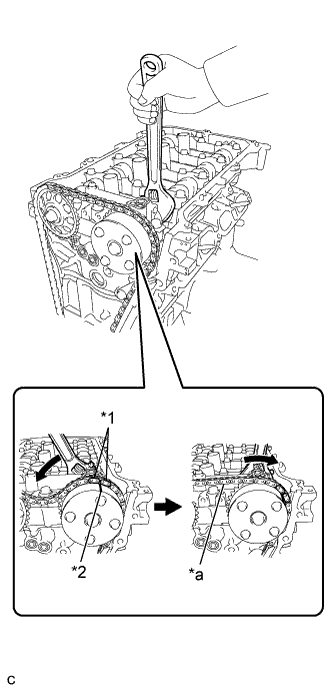

Put the camshaft timing gear and camshaft together with the straight pin and key groove misaligned as shown in the illustration.

| *1 | Straight Pin |

| *2 | Key Groove |

|

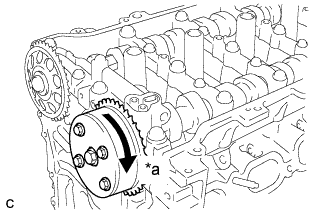

Turn the camshaft timing gear as shown in the illustration while pushing it gently against the camshaft. Push further at the position where the pin fits into the groove.

| *1 | Straight Pin |

| *2 | Key Groove |

|

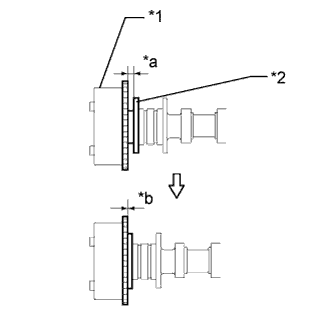

Check that there is no clearance between the camshaft timing gear and camshaft flange.

| *1 | Camshaft Timing Gear |

| *2 | Flange |

| *a | Clearance |

| *b | No Clearance |

|

Tighten the flange bolt with the camshaft timing gear secured in place.

|

Check that the camshaft timing gear can move in the retard direction (clockwise) and is locked in the most retarded position.

| *a | Lock |

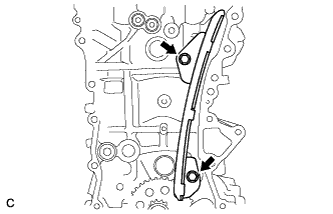

| 9. INSTALL NO. 1 CHAIN VIBRATION DAMPER |

|

Install the chain vibration damper with the 2 bolts.

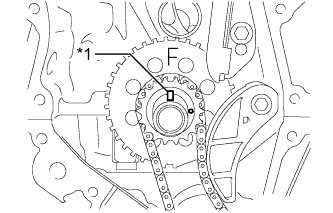

| 10. SET NO. 1 CYLINDER TO TDC/COMPRESSION |

|

Temporarily install the crankshaft pulley bolt.

| *1 | Timing Gear Key |

Turn the crankshaft to position the timing gear key to the top.

|

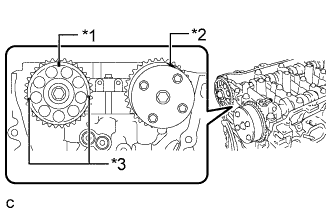

Check that the timing marks on the camshaft timing gear and camshaft timing sprocket are aligned as shown in the illustration.

| *1 | Timing Mark (Rectangle) |

| *2 | Timing Mark |

| *3 | Mark (Circle) |

Remove the crankshaft pulley bolt.

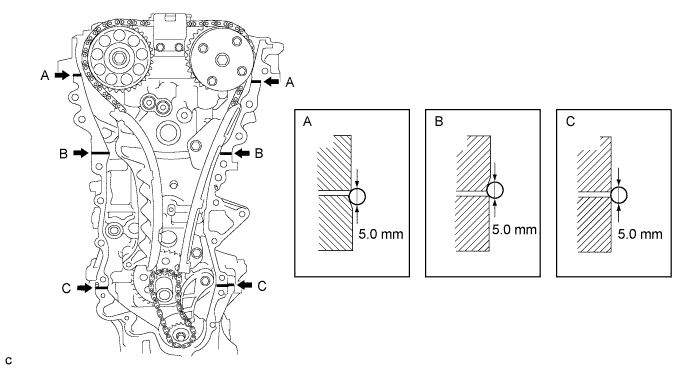

| 11. INSTALL CHAIN SUB-ASSEMBLY |

|

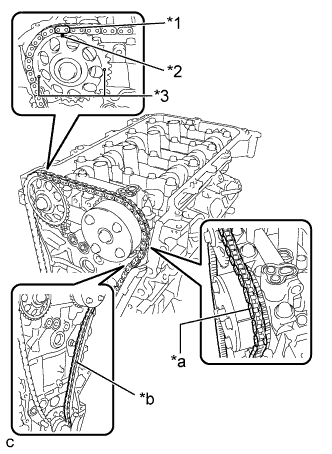

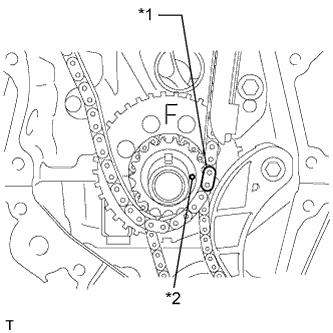

Align the mark plate (orange) with the timing mark as shown in the illustration and install the chain.

| *1 | Mark Plate (Orange) |

| *2 | Timing Mark (Rectangle) |

| *3 | Mark (Circle) |

| *a | Place the Chain on the Sprocket |

| *b | Pass the Chain through the Damper |

|

Place the chain on the crankshaft without passing it around the shaft.

|

Hold the hexagonal portion of the camshaft with a wrench and turn the camshaft timing gear counterclockwise to align the mark plate (orange) and timing mark, and then install the chain.

| *1 | Mark Plate (Orange) |

| *2 | Timing Mark |

| *a | Tension the Chain |

Hold the hexagonal portion of the camshaft with a wrench and turn the camshaft timing gear clockwise.

|

Align the mark plate (yellow or pink) and timing mark and install the chain to the crankshaft timing gear.

| *1 | Mark Plate (Yellow or Pink) |

| *2 | Timing Mark |

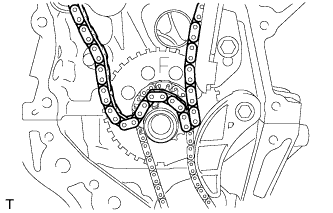

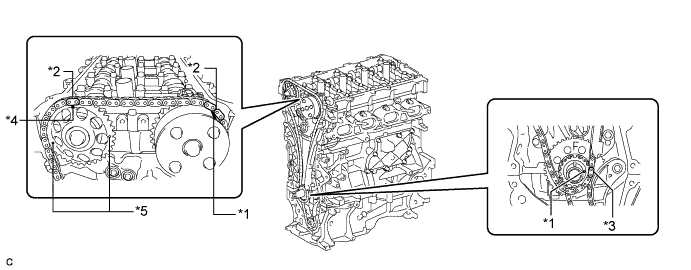

| 12. CHECK NO. 1 CYLINDER TO TDC/COMPRESSION |

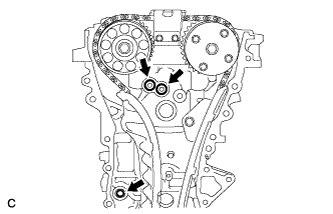

Check each timing mark at TDC/compression.

| *1 | Timing Mark | *2 | Mark Plate (Orange) |

| *3 | Mark Plate (Yellow or Pink) | *4 | Timing Mark (Rectangle) |

| *5 | Mark (Circle) | - | - |

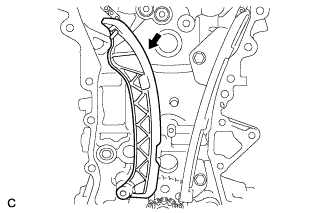

| 13. INSTALL NO. 2 CHAIN VIBRATION DAMPER |

|

Install the No. 2 chain vibration damper with the 2 bolts.

| 14. INSTALL CHAIN TENSIONER SLIPPER |

|

Install the chain tensioner slipper to the cylinder block.

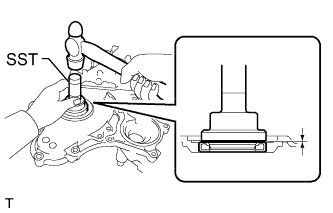

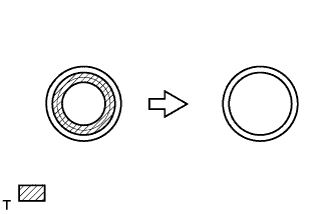

| 15. INSTALL TIMING CHAIN COVER OIL SEAL |

|

Using SST, tap in a new oil seal until its surface is flush with the timing chain cover edge.

Apply MP grease to the lip of the oil seal.

| 16. INSTALL TIMING CHAIN COVER SUB-ASSEMBLY |

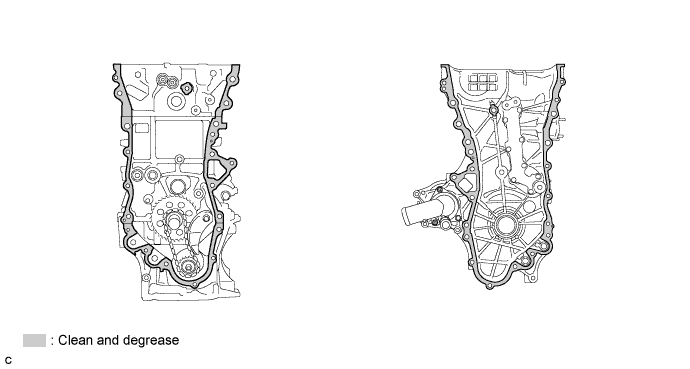

Remove any old packing (FIPG) material and be careful not to drop any oil on the contact surfaces of the timing chain cover, cylinder head, and cylinder block.

|

Install 3 new O-rings.

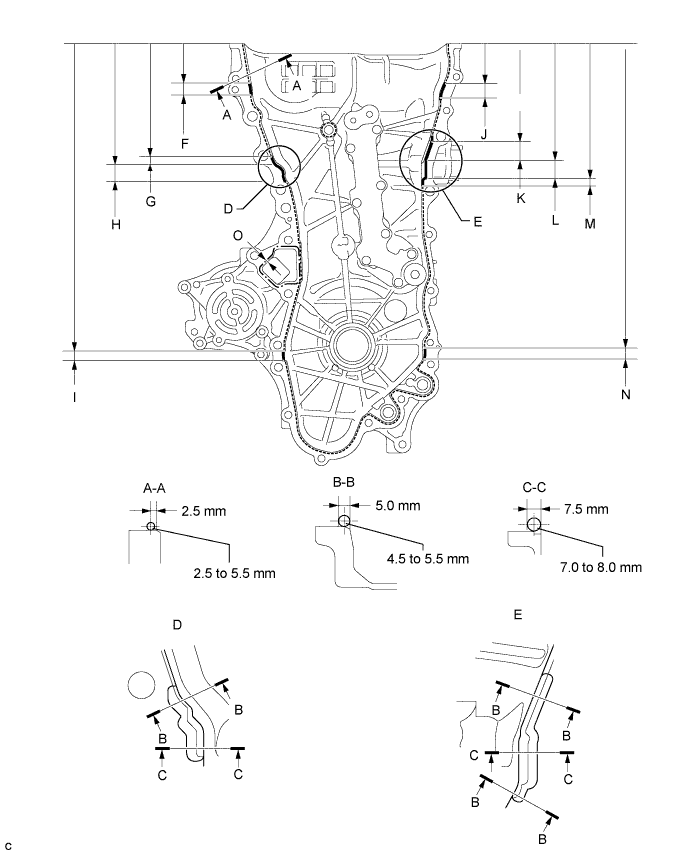

Apply seal packing as shown in the illustration.

Apply seal packing to the timing chain cover in a line as shown in the following illustration.

| Item | Seal Packing |

| Dashed line | Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent |

| Continuous line | |

| Alternate long and short dashed line | Toyota Genuine Seal Packing 1282B, Three Bond 1282B or equivalent |

| Area | Seal Packing Diameter | Distance from Edge of Cover to: | Seal Packing Application Length | Distance from Top of Cover to Top of Seal Packing |

| Dashed line | 2.5 to 3.0 mm (0.0984 to 0.118 in.) | Center of seal packing 2.5 mm (0.0984 in.) | - | - |

| Continuous line | 4.5 to 5.5 mm (0.177 to 0.217 in.) or 7.0 to 8.0 mm (0.276 to 0.315 in.) | - | - | - |

| Alternate long and short dashed line | 4.0 mm (0.157 in.) | Center of seal packing 3.0 mm (0.118 in.) | - | - |

| A - A | 2.5 to 3.0 mm (0.0984 to 0.118 in.) | Center of seal packing 2.5 mm (0.0984 in.) | - | - |

| B - B | 4.5 to 5.5 mm (0.177 to 0.217 in.) | Opposite edge of seal packing 5.0 mm (0.197 in.) | - | - |

| C - C | 7.0 to 8.0 mm (0.276 to 0.315 in.) | Opposite edge of seal packing 7.5 mm (0.295 in.) | - | - |

| F | 4.5 to 5.5 mm (0.177 to 0.217 in.) | - | 15.5 mm (0.610 in.) | 50.4 mm (1.98 in.) |

| G | 4.5 to 5.5 mm (0.177 to 0.217 in.) | - | 10.3 mm (0.406 in.) | 143.1 mm (5.63 in.) |

| H | 7.0 to 8.0 mm (0.276 to 0.315 in.) | - | 19.5 mm (0.768 in.) | 153.4 mm (6.04 in.) |

| I | 4.5 to 5.5 mm (0.177 to 0.217 in.) | - | 16.0 mm (0.630 in.) | 385.8 mm (1.27 ft.) |

| J | 4.5 to 5.5 mm (0.177 to 0.217 in.) | - | 18.6 mm (0.732 in.) | 51.4 mm (2.02 in.) |

| K | 4.5 to 5.5 mm (0.177 to 0.217 in.) | - | 25.3 mm (0.996 in.) | 121.9 mm (4.80 in.) |

| L | 7.0 to 8.0 mm (0.276 to 0.315 in.) | - | 25.8 mm (1.02 in.) | 147.2 mm (5.80 in.) |

| M | 4.5 to 5.5 mm (0.177 to 0.217 in.) | - | 5.1 mm (0.201 in.) | 173.0 mm (6.81 in.) |

| N | 4.5 to 5.5 mm (0.177 to 0.217 in.) | - | 14.6 mm (0.575 in.) | 385.8 mm (1.27 ft.) |

| O | 4.0 mm (0.157 in.) | Center of seal packing 3.0 mm (0.118 in.) | - | - |

Clean the bolt and fitting hole.

Install the timing chain cover.

|

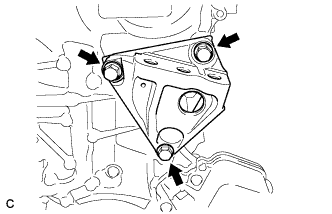

Temporarily tighten the engine mounting bracket RH with the 3 bolts.

| Item | Length |

| Bolt | 80 mm (3.15 in.) |

|

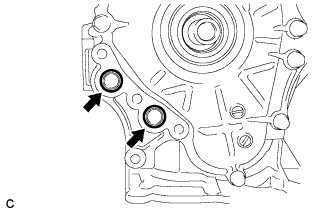

Install 2 new O-rings.

|

Temporarily tighten the oil filter bracket with the 4 bolts.

| Item | Length |

| Bolt | 35 mm (1.38 in.) |

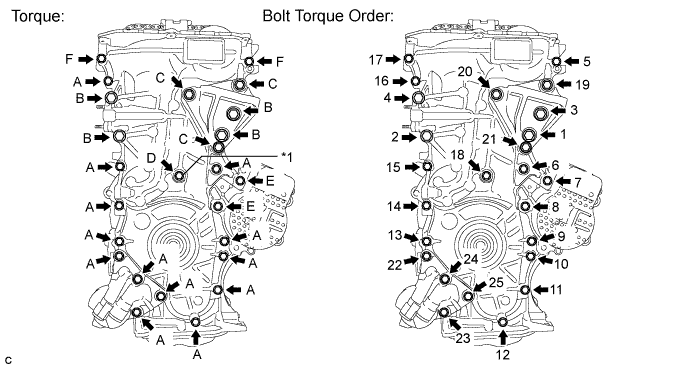

Install the timing chain cover with the 25 bolts and seal washer as shown in the illustration.

| *1 | Seal Washer | - | - |

| Item | Length |

| Bolt A, F | 35 mm (1.38 in.) |

| Bolt B | 55 mm (2.16 in.) |

| Bolt C | 80 mm (3.15 in.) |

| Bolt D | 40 mm (1.57 in.) |

| Bolt E | 55 mm (2.16 in.) |

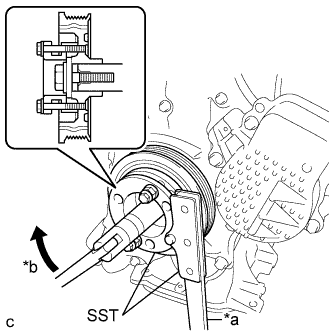

| 17. INSTALL CRANKSHAFT PULLEY |

Align the pulley set key with the key groove of the pulley.

|

Using SST, hold the pulley in place and tighten the bolt.

| *a | Hold |

| *b | Turn |

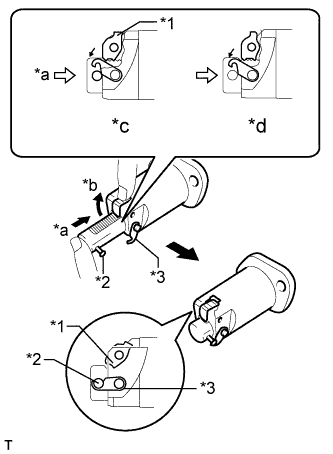

| 18. INSTALL NO. 1 CHAIN TENSIONER ASSEMBLY |

|

Release the cam, and then fully push in the plunger and engage the hook to the pin so that the plunger is in the position shown in the illustration.

| *1 | Cam |

| *2 | Pin |

| *3 | Hook |

| *a | Push |

| *b | Raise |

| *c | CORRECT |

| *d | INCORRECT |

|

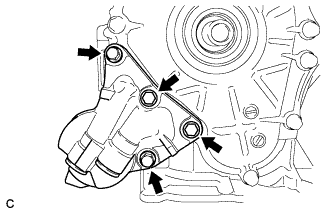

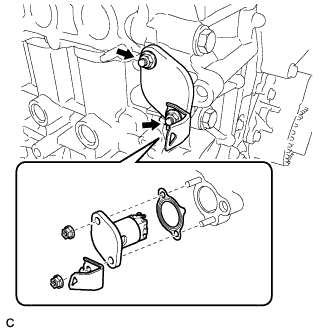

Install a new gasket, the bracket and chain tensioner with the 2 nuts.

|

Rotate the crankshaft counterclockwise slightly and check that the hook becomes released.

| *1 | Pin |

| *2 | Hook |

| *a | Push |

| *b | Turn |

| *c | Disconnect |

|

Turn the crankshaft clockwise and check that the plunger is extended.

| *1 | Plunger |

| *a | Turn |

| *b | Plunger Extended |

| 19. INSTALL SPARK PLUG TUBE GASKET |

|

Using a cutter knife, cut off the seal part of the removed gasket.

| Part to Cut Off |

|

Using a hammer and the plug tube gasket which has had the sealing part cut off, uniformly tap in a new plug tube gasket all the way.

| *1 | Plug Tube Gasket without Sealing Part |

| *2 | New Plug Tube Gasket |

Return the claws of the ventilation baffle plate to their original positions.

| 20. INSTALL CYLINDER HEAD COVER GASKET |

|

Install a new cylinder head cover gasket to the cylinder head cover.

| *1 | Cylinder Head Cover |

| *2 | Cylinder Head Cover Gasket |

| 21. INSTALL CYLINDER HEAD COVER SUB-ASSEMBLY |

|

Install 2 new gaskets to the camshaft bearing cap.

|

Apply seal packing as shown the illustration.

|

Install the cylinder head cover with a new seal washer and the 13 bolts.

|

| *1 | Timing Chain Cover |

| *2 | Camshaft Housing |

| *3 | Cylinder Head Cover Gasket |

| 22. INSTALL IGNITION COIL ASSEMBLY |

|

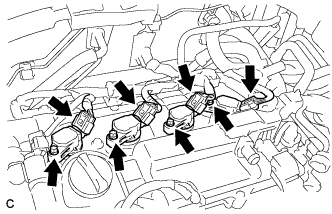

Install the 4 ignition coils with the 4 bolts.

Connect the 4 ignition coil connectors.

| 23. INSTALL FUEL INJECTOR ASSEMBLY |

|

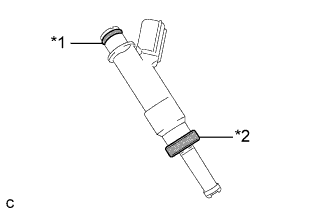

Install a new insulator and O-ring to each fuel injector assembly.

| *1 | O-ring |

| *2 | Insulator |

Apply a light coat of gasoline or spindle oil to the contact surfaces of the new O-ring on each fuel injector assembly.

|

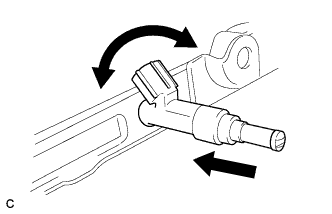

While turning the fuel injector assembly left and right, install it onto the fuel delivery pipe sub-assembly.

| 24. INSTALL NO. 1 DELIVERY PIPE SPACER |

|

Install the 2 No. 1 delivery pipe spacers onto the cylinder head.

| *a | Delivery Pipe Side |

| *b | Cylinder Head Side |

| 25. INSTALL FUEL DELIVERY PIPE SUB-ASSEMBLY |

|

Install the fuel delivery pipe sub-assembly with the 4 fuel injector assemblies and install the 2 bolts.

|

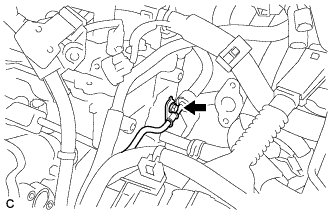

Install the bolt to secure the fuel delivery pipe sub-assembly.

| 26. INSTALL FUEL VAPOR FEED PIPE |

|

Install the fuel vapor feed pipe with the bolt.

| 27. INSTALL INTAKE MANIFOLD |

Install a new No. 1 intake manifold to head gasket to the intake manifold.

|

Install the intake manifold with the 2 bolts and 2 nuts.

|

Connect the fuel vapor feed hose and ventilation hose.

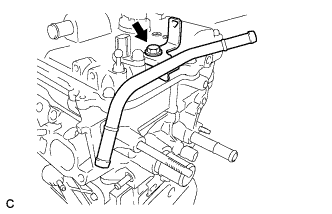

Install a new O-ring to the engine oil level dipstick guide sub-assembly.

Apply a light coat of engine oil to the O-ring.

|

Install the engine oil level dipstick guide sub-assembly with the 2 bolts and connect the wire harness clamp.

Install the engine oil level dipstick.

|

Connect the 2 wire harness clamps and 3 connectors.

| 28. INSTALL EGR WITH COOLER PIPE SUB-ASSEMBLY |

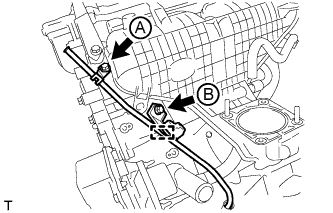

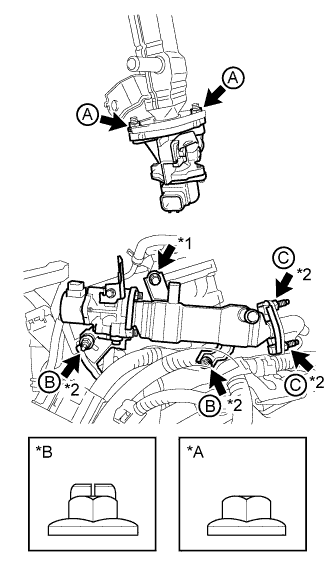

|

Temporarily install a new gasket and the EGR cooler sub-assembly with the 2 nuts (A).

| *A | Nut (C), Type A |

| *B | Nut (C), Type B |

| *1 | Bolt |

| *2 | Stud Bolt and Nut |

Install 2 new gaskets and set the EGR valve with cooler assembly in place.

Using an E8 "TORX" wrench, install the 4 stud bolts.

Temporarily install the 4 nuts (B and C) and bolt.

Tighten the 2 nuts (A).

Tighten the 2 nuts (B) and bolt.

Tighten the 2 nuts (C).

|

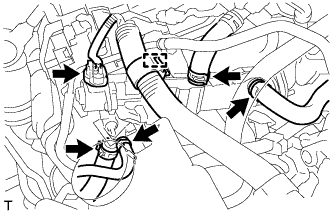

Connect the connector, wire harness clamp and 4 water hoses.

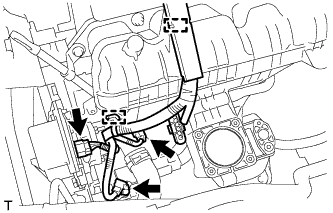

| 29. INSTALL EGR VALVE ASSEMBLY |

|

Temporarily install a new gasket and the EGR valve assembly with the 2 nuts (A).

| *A | Nut (C), Type A |

| *B | Nut (C), Type B |

| *1 | Bolt |

| *2 | Stud Bolt and Nut |

Install 2 new gaskets and set the EGR valve with cooler assembly in place.

Using an E8 "TORX" wrench, install the 4 stud bolts.

Temporarily install the 4 nuts (B and C) and bolt.

Tighten the 2 nuts (A).

Tighten the 2 nuts (B) and bolt.

Tighten the 2 nuts (C).

|

Connect the connector, wire harness clamp and 4 water hoses.

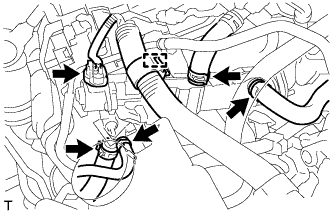

| 30. INSTALL EGR PIPE ASSEMBLY |

|

Install 2 new gaskets and EGR pipe assembly with the 4 bolts.

|

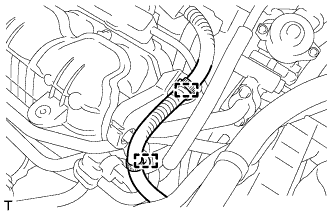

Install the wire harness support with the bolt.

|

Connect the 2 wire harness clamps.

| 31. INSTALL ENGINE OIL LEVEL DIPSTICK GUIDE |

Apply a light coat of engine oil to a new O-ring.

Install the O-ring to the engine oil level dipstick guide.

|

Install the engine oil level dipstick guide with the 2 bolts.

Connect the clamp to the engine oil level dipstick guide.

Install the oil dipstick.

| 32. INSTALL THROTTLE BODY ASSEMBLY |

|

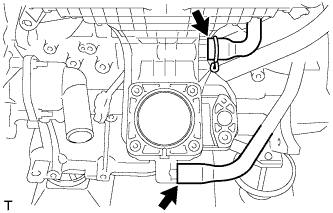

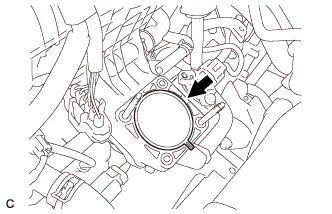

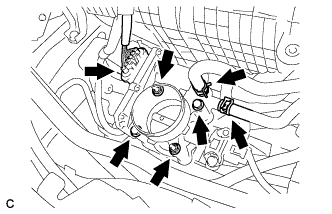

Install a new gasket onto the intake manifold.

|

Install the throttle body assembly with the 2 bolts and 2 nuts.

Connect the 2 water by-pass hoses and throttle body connector.

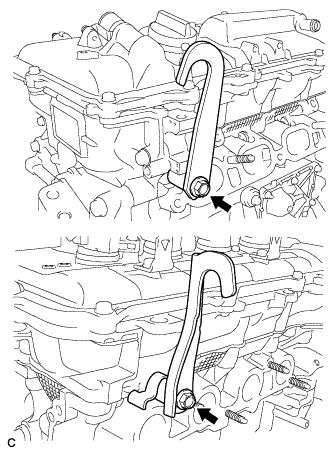

| 33. INSTALL ENGINE HANGERS |

|

Install the 2 engine hangers with the 2 bolts.

| Part Name | Part No. |

| No. 1 engine hanger | 12281-37021 |

| No. 2 engine hanger | 12282-37011 |

| Bolt | 91552-81050 |

| 34. REMOVE ENGINE ON ENGINE STAND |

Remove the bolts and engine on engine stand.

| 35. INSTALL ENGINE ASSEMBLY WITH TRANSAXLE |

Install the engine assembly with transaxle (Click here).