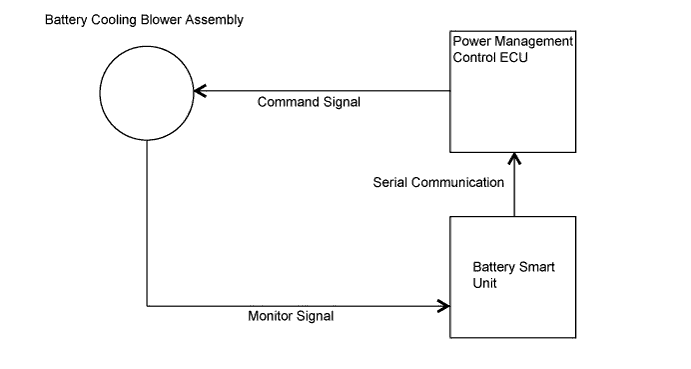

DTC P0A84-123 Hybrid Battery Pack Cooling Fan 1 |

| DTC No. | DTC Detection Condition | Trouble Area |

| P0A84-123 | When the output voltage of the battery cooling blower assembly (VM) is too low compared to the target control voltage range (1 trip detection) |

|

| 1.CHECK FOR DTCS (DTC P0AFC-123 IS OUTPUT) |

Connect the intelligent tester to the DLC3.

Turn the power switch on (IG).

Enter the following menus: Powertrain / Hybrid Control / Trouble Codes.

Read output DTCs (Click here).

| Result | Proceed to |

| P0AFC-123 is not output. | A |

| P0AFC-123 is also output. | B |

Disconnect the intelligent tester from the DLC3.

|

| ||||

| A | |

| 2.PERFORM ACTIVE TEST USING INTELLIGENT TESTER |

Remove the rear side seatback assembly RH (Click here).

Connect the intelligent tester to the DLC3.

Turn the power switch on (IG).

Enter the following menus: Powertrain / Hybrid Control / Active Test / Driving the Battery Cooling Fan.

Select air volume mode 6 in the "Driving the Battery Cooling Fan" active test to operate the battery cooling blower assembly.

Check that the fan operates and air is sucked into the inlet duct.

Install the rear side seatback assembly RH (Click here).

|

| ||||

| OK | |

| 3.CHECK HARNESS AND CONNECTOR (BATTERY COOLING BLOWER - BATTERY SMART UNIT) |

Disconnect the cable from the negative (-) battery terminal.

Check that the service plug grip is not installed.

Remove the No. 1 hybrid vehicle battery carrier bracket sub-assembly (Click here).

|

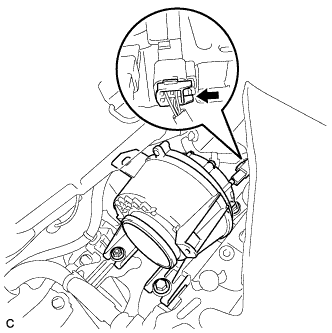

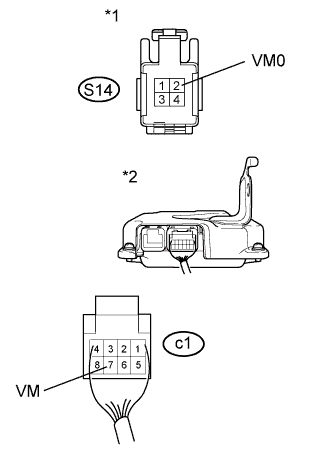

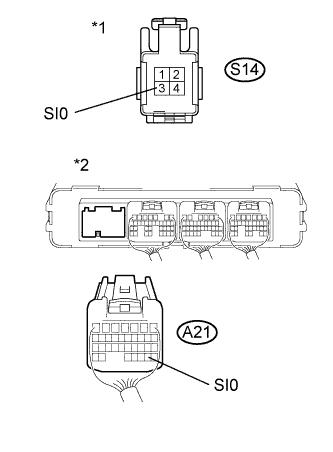

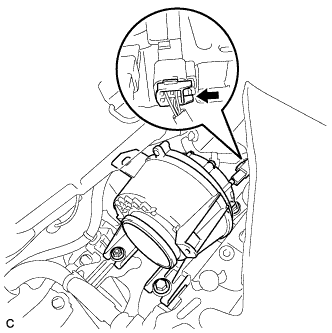

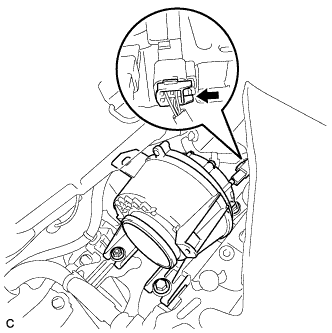

Disconnect the S14 connector of the battery cooling blower assembly.

|

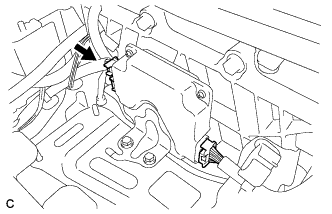

Disconnect the c1 connector of the battery smart unit.

|

Measure the resistance according to the value(s) in the table below.

| Tester Connection | Switch Condition | Specified Condition |

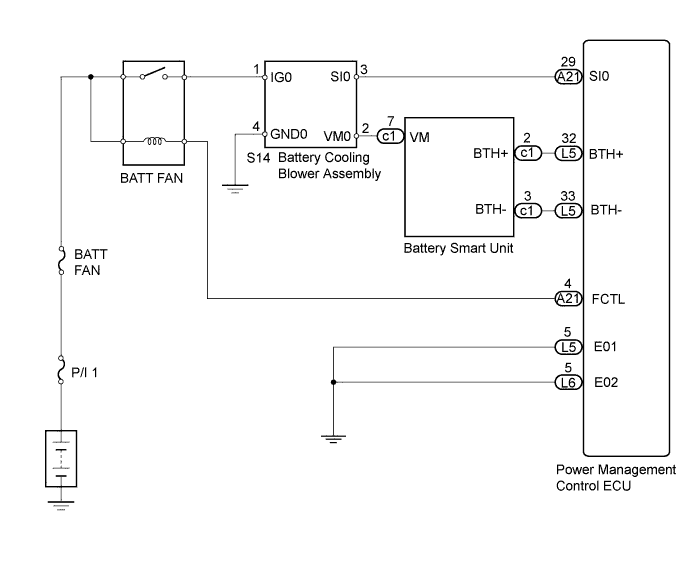

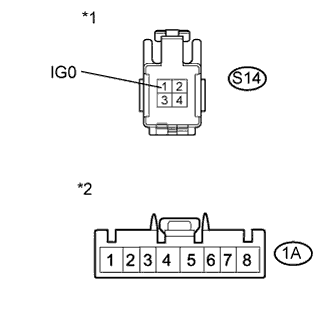

| S14-2 (VM0) - c1-7 (VM) | Power switch off | Below 1 Ω |

| Tester Connection | Switch Condition | Specified Condition |

| S14-2 (VM0) or c1-7 (VM) - Body ground | Power switch off | 10 kΩ or higher |

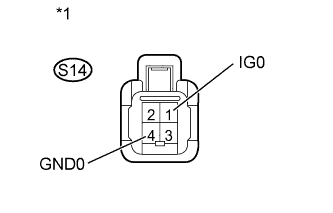

| *1 | Front view of wire harness connector (to Battery Cooling Blower Assembly) |

| *2 | Rear view of wire harness connector (to Battery Smart Unit) |

Connect the S14 connector of the battery cooling blower assembly.

Connect the c1 connector of the battery smart unit.

Install the No. 1 hybrid vehicle battery carrier bracket sub-assembly (Click here).

|

| ||||

| OK | |

| 4.CHECK BATTERY COOLING BLOWER ASSEMBLY (VOLTAGE) |

Disconnect the cable from the negative (-) battery terminal.

Check that the service plug grip is not installed.

Remove the No. 1 hybrid vehicle battery carrier bracket sub-assembly (Click here).

Connect the cable to the negative (-) battery terminal.

Connect the intelligent tester to the DLC3.

Turn the power switch on (IG).

Enter the following menus: Powertrain / Hybrid Control / Active Test / Driving the Battery Cooling Fan.

Enter the following menus: All Data / VMF Fan Motor Voltage 1.

Select each air volume mode (1 to 6) in the "Driving the Battery Cooling Fan" active test to operate the battery cooling blower assembly.

|

While the cooling fan is operating, compare the value in the data list (VMF Fan Motor Voltage 1) with the voltage value that was actually measured at the battery cooling blower assembly connector.

| Tester Connection | Condition | Specified Condition |

| S14-2 (VM0) - S14-4 (GND0) | Battery cooling blower is operating | Difference between the value in the Data List (VMF Fan Motor Voltage 1) and the actual measurement value is 1 V or less. |

| *1 | Component with harness connected (Battery Cooling Blower assembly) |

Install the No. 1 hybrid vehicle battery carrier bracket sub-assembly (Click here).

|

| ||||

| OK | ||

| ||

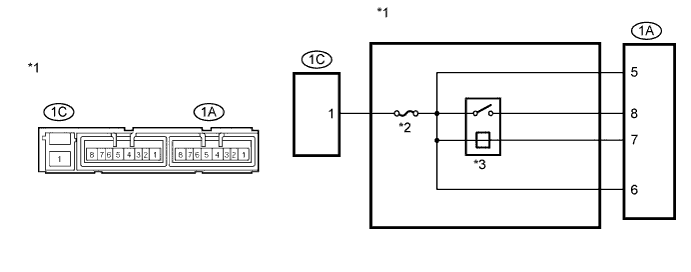

| 5.CHECK INTEGRATION NO.2 RELAY (BATT FAN) |

Remove the integration relay from the engine room junction block assembly (Click here).

Measure the resistance according to the value(s) in the table below.

| Tester Connection | Condition | Specified Condition |

| 1C-1 - 1A-8 | Battery voltage is applied across terminals 1A-6 and 1A-7 | Below 1 Ω |

| No battery voltage is applied across terminals 1A-6 and 1A-7 | 10 kΩ or higher |

| *1 | Integration Relay | *2 | BATT FAN Fuse |

| *3 | BATT FAN Relay | - | - |

Install the integration relay (Click here).

|

| ||||

| OK | |

| 6.CHECK HARNESS AND CONNECTOR (VOLTAGE) |

Disconnect the cable from the negative (-) battery terminal.

Check that the service plug grip is not installed.

Remove the No. 1 hybrid vehicle battery carrier bracket sub-assembly (Click here).

Connect the cable to the negative (-) battery terminal.

Connect the intelligent tester to the DLC3.

Turn the power switch on (IG).

Enter the following menus: Powertrain / Hybrid Control / Active Test / Driving the Battery Cooling Fan.

Enter the following menus: All Data / VMF Fan Motor Voltage 1.

Select each air volume mode (1 to 6) in the "Driving the Battery Cooling Fan" active test to operate the battery cooling blower assembly.

|

Measure the voltage according to the value(s) in the table below.

| Tester Connection | Condition | Specified Condition |

| S14-1 (IG0) - Body ground | Battery cooling blower is operating | 11 to 14 V |

| *1 | Component with harness connected (Battery Cooling Blower Assembly) |

Turn the power switch off.

Install the No. 1 hybrid vehicle battery carrier bracket sub-assembly (Click here).

|

| ||||

| OK | |

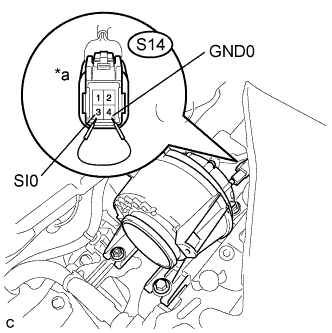

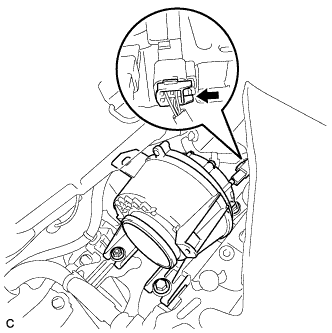

| 7.CHECK BATTERY COOLING BLOWER ASSEMBLY |

Disconnect the cable from the negative (-) battery terminal.

Check that the service plug grip is not installed.

Remove the No. 1 hybrid vehicle battery carrier bracket sub-assembly (Click here).

Connect the cable to the negative (-) battery terminal.

Turn the power switch on (IG).

|

Using a service wire, connect terminals 3 (SI0) and 4 (GND0) of the battery cooling blower assembly connector.

| Tester Connection | Switch Condition | Specified Condition |

| S14-3 (SI0) - S14-4 (GND0) | Power switch on (IG) | Fan operates |

| *1 | Component with harness connected (Battery Cooling Blower Assembly) |

Turn the power switch off.

Install the No. 1 hybrid vehicle battery carrier bracket sub-assembly (Click here).

|

| ||||

| OK | |

| 8.CHECK HARNESS AND CONNECTOR (BATTERY COOLING BLOWER - POWER MANAGEMENT CONTROL ECU) |

Disconnect the cable from the negative (-) battery terminal.

Check that the service plug grip is not installed.

Remove the No. 1 hybrid vehicle battery carrier bracket sub-assembly (Click here).

|

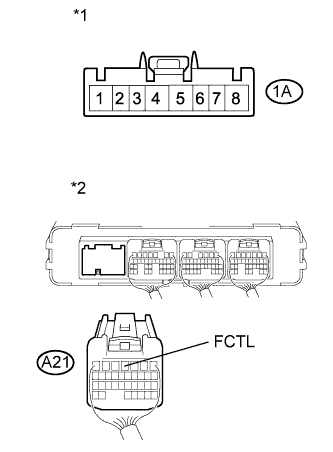

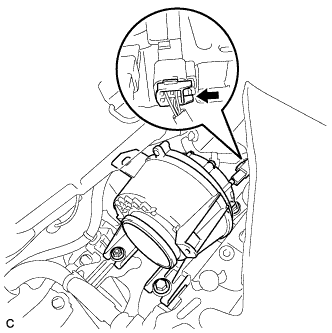

Remove the S14 connector of the battery cooling blower assembly.

Disconnect the A21 connector of the power management control ECU (Click here).

|

Measure the resistance according to the value(s) in the table below.

| Tester Connection | Switch Condition | Specified Condition |

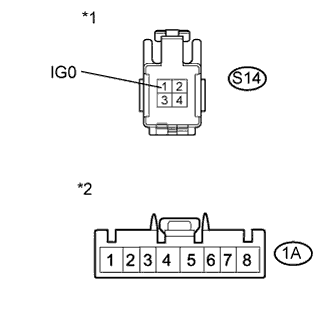

| S14-3 (SI0) - A21-29 (SI0) | Power switch off | Below 1 Ω |

| Tester Connection | Switch Condition | Specified Condition |

| S14-3 (SI0) or A21-29 (SI0) - Body ground | Power switch off | 10 kΩ or higher |

| *1 | Front view of wire harness connector (to Battery Cooling Blower Assembly) |

| *2 | Rear view of wire harness connector (to Power Management Control ECU) |

Connect the cable to the negative (-) battery terminal.

Turn the power switch on (IG).

Measure the voltage according to the value(s) in the table below.

| Tester Connection | Switch Condition | Specified Condition |

| S14-3 (SI0) - Body ground | Power switch on (IG) | Below 1 V |

Turn the power switch off.

Connect the S14 connector of the battery cooling blower assembly.

Install the No. 1 hybrid vehicle battery carrier bracket sub-assembly (Click here).

Connect the A21 connector of the power management control ECU (Click here).

|

| ||||

| OK | ||

| ||

| 9.CHECK HARNESS AND CONNECTOR (INTEGRATION RELAY - POWER MANAGEMENT CONTROL ECU) |

Disconnect the cable from the negative (-) battery terminal.

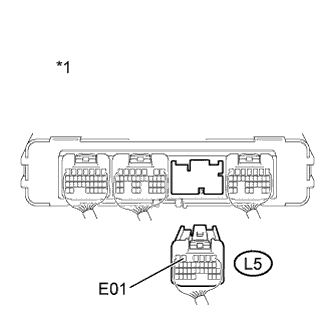

Disconnect the A21 connector of the power management control ECU (Click here).

Remove the integration relay (Click here).

|

Measure the resistance according to the value(s) in the table below.

| Tester Connection | Switch Condition | Specified Condition |

| 1A-7 - A21-4 (FCTL) | Power switch off | Below 1 Ω |

| *1 | Front view of wire harness connector (to Integration Relay) |

| *2 | Rear view of wire harness connector (to Power Management Control ECU) |

Connect the cable to the negative (-) battery terminal.

Measure the voltage according to the value(s) in the table below.

| Tester Connection | Switch Condition | Specified Condition |

| A21-4 (FCTL) - Body ground | Power switch off | Below 1 V |

| Power switch on (IG) | Below 1 V |

Connect the A21 connector of the power management control ECU (Click here).

Install the integration relay (Click here).

|

| ||||

| OK | |

| 10.CHECK HARNESS AND CONNECTOR (POWER MANAGEMENT CONTROL ECU - BODY GROUND) |

Disconnect the cable from the negative (-) battery terminal.

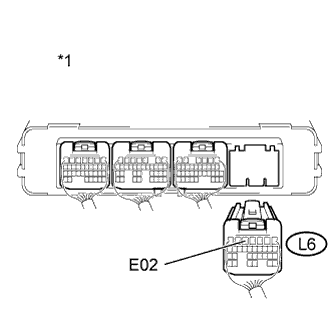

Disconnect the L5 connector of the power management control ECU (Click here).

|

Measure the resistance according to the value(s) in the table below.

| Tester Connection | Switch Condition | Specified Condition |

| L5-5 (E01) - Body ground | Power switch off | Below 1 Ω |

| *1 | Rear view of wire harness connector (to Power Management Control ECU) |

Connect the L5 connector of the power management control ECU (Click here).

Connect the cable to the negative (-) battery terminal.

|

| ||||

| OK | |

| 11.CHECK HARNESS AND CONNECTOR (POWER MANAGEMENT CONTROL ECU - BODY GROUND) |

Disconnect the cable from the negative (-) battery terminal.

Disconnect the L6 connector of the power management control ECU (Click here).

|

Measure the resistance according to the value(s) in the table below.

| Tester Connection | Switch Condition | Specified Condition |

| L6-5 (E02) - Body ground | Power switch off | Below 1 Ω |

| *1 | Rear view of wire harness connector (to Power Management Control ECU) |

Connect the L6 connector of the power management control ECU (Click here).

Connect the cable to the negative (-) battery terminal.

|

| ||||

| OK | |

| 12.CHECK HARNESS AND CONNECTOR (INTEGRATION RELAY - BATTERY COOLING BLOWER ASSEMBLY) |

Disconnect the cable from the negative (-) battery terminal.

Remove the integration relay (Click here).

Remove the No. 1 hybrid vehicle battery carrier bracket sub-assembly (Click here).

|

Disconnect the S14 connector of the battery cooling blower assembly.

|

Measure the resistance according to the value(s) in the table below.

| Tester Connection | Switch Condition | Specified Condition |

| 1A-8 - S14-1 (IG0) | Power switch off | Below 1 Ω |

| *1 | Front view of wire harness connector (to Battery Cooling Blower Assembly) |

| *2 | Front view of wire harness connector (to Integration Relay) |

Install the integration relay (Click here).

Connect the S14 connector of the battery cooling blower assembly.

Install the No. 1 hybrid vehicle battery carrier bracket sub-assembly (Click here).

Connect the cable to the negative (-) battery terminal.

|

| ||||

| OK | ||

| ||

| 13.REPLACE INTEGRATION NO. 2 RELAY |

Replace the integration relay (Click here).

| NEXT | |

| 14.CHECK HARNESS AND CONNECTOR (INTEGRATION RELAY - BATTERY COOLING BLOWER ASSEMBLY) |

Disconnect the cable from the negative (-) battery terminal.

Remove the integration relay (Click here).

Remove the No. 1 hybrid vehicle battery carrier bracket sub-assembly (Click here).

|

Disconnect the S14 connector of the battery cooling blower assembly.

|

Measure the resistance according to the value(s) in the table below.

| Tester Connection | Switch Condition | Specified Condition |

| S14-1 (IG0) - Terminals other than 1A-8 and body ground | Power switch off | 10 kΩ or higher |

| *1 | Front view of wire harness connector (to Battery Cooling Blower Assembly) |

| *2 | Front view of wire harness connector (to Integration Relay) |

Install the integration relay (Click here).

Connect the S14 connector of the battery cooling blower assembly.

Install the No. 1 hybrid vehicle battery carrier bracket sub-assembly (Click here).

Connect the cable to the negative (-) battery terminal.

|

| ||||

| OK | |

| 15.CHECK BATTERY COOLING BLOWER ASSEMBLY |

Disconnect the cable from the negative (-) battery terminal.

Remove the No. 1 hybrid vehicle battery carrier bracket sub-assembly (Click here).

|

Disconnect the S14 connector of the battery cooling blower assembly.

|

Measure the resistance according to the value(s) in the table below.

| Tester Connection | Switch Condition | Specified Condition |

| S14-1 (IG0) - S14-4 (GND0) and body ground | Power switch off | 10 kΩ or higher |

| *1 | Component without harness connected (Battery Cooling Blower Assembly) |

Connect the S14 connector of the battery cooling blower assembly.

Install the No. 1 hybrid vehicle battery carrier bracket sub-assembly (Click here).

Connect the cable to the negative (-) battery terminal.

|

| ||||

| OK | ||

| ||