ENTRY AND START SYSTEM (for Start Function) > Power Source Mode does not Change to ON (ACC) |

| 1.CHECK HARNESS OR CONNECTOR (AUXILIARY BATTERY - POWER MANAGEMENT CONTROL ECU) |

Disconnect the L5 and L6 connectors from the power management control ECU.

Measure the voltage according to the value(s) in the table below.

| Tester Connection | Condition | Specified Condition |

| L5-1 (AM22) - Body ground | Always | 9.5 to 16 V |

| L6-7 (AM21) - Body ground | Always | 9.5 to 16 V |

|

| ||||

| OK | |

| 2.CHECK HARNESS OR CONNECTOR (POWER MANAGEMENT CONTROL ECU - BODY GROUND) |

Measure the resistance according to the value(s) in the table below.

| Tester Connection | Condition | Specified Condition |

| L5-5 (E01) - Body ground | Always | Below 1 Ω |

| L5-6 (E1) - Body ground | Always | Below 1 Ω |

| L6-4 (E12) - Body ground | Always | Below 1 Ω |

| L6-5 (E02) - Body ground | Always | Below 1 Ω |

|

| ||||

| OK | |

| 3.INSPECT INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY |

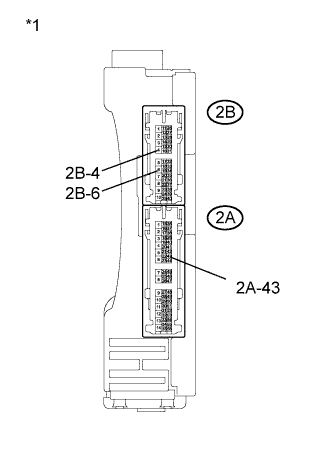

|

Remove the instrument panel junction block assembly.

Measure the resistance according to the value(s) in the table below.

| Tester Connection | Condition | Specified Condition |

| 2A-43 - 2B-4 | 20°C (68°F) | 81.49 to 118.98 Ω |

| 2A-43 - 2B-6 | 20°C (68°F) | 81.49 to 118.98 Ω |

| 2B-4 - 2B-6 | Always | Below 1 Ω |

| *1 | Component without harness connected (Instrument Panel Junction Block Assembly) |

|

| ||||

| OK | |

| 4.CHECK HARNESS AND CONNECTOR (POWER MANAGEMENT CONTROL ECU - INSTRUMENT PANEL J/B) |

Measure the resistance according to the value(s) in the table below.

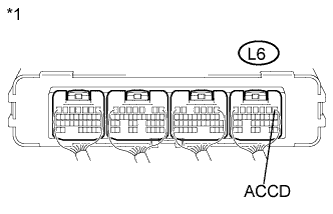

| Tester Connection | Condition | Specified Condition |

| L6-1 (ACCD) - 2A-43 | Always | Below 1 Ω |

| L6-1 (ACCD) - Body ground | Always | 10 kΩ or higher |

|

| ||||

| OK | |

| 5.CHECK HARNESS AND CONNECTOR (INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY - BODY GROUND) |

Measure the resistance according to the value(s) the table below.

| Tester Connection | Condition | Specified Condition |

| 2B-4 - Body ground | Always | Below 1 Ω |

| 2B-6 - Body ground | Always | Below 1 Ω |

|

| ||||

| OK | |

| 6.INSPECT POWER MANAGEMENT CONTROL ECU |

|

Reinstall the instrument panel junction block assembly.

Reconnect the L5 and L6 connectors.

Measure the voltage according to the value(s) in the table below.

| Tester Connection | Condition | Specified Condition |

| L6-1 (ACCD) - Body ground | Power switch on (ACC) | Output voltage at terminal AM21 or AM22 is -2.5 V or more |

| *1 | Component with harness connected (Power Management Control ECU) |

|

| ||||

| OK | ||

| ||