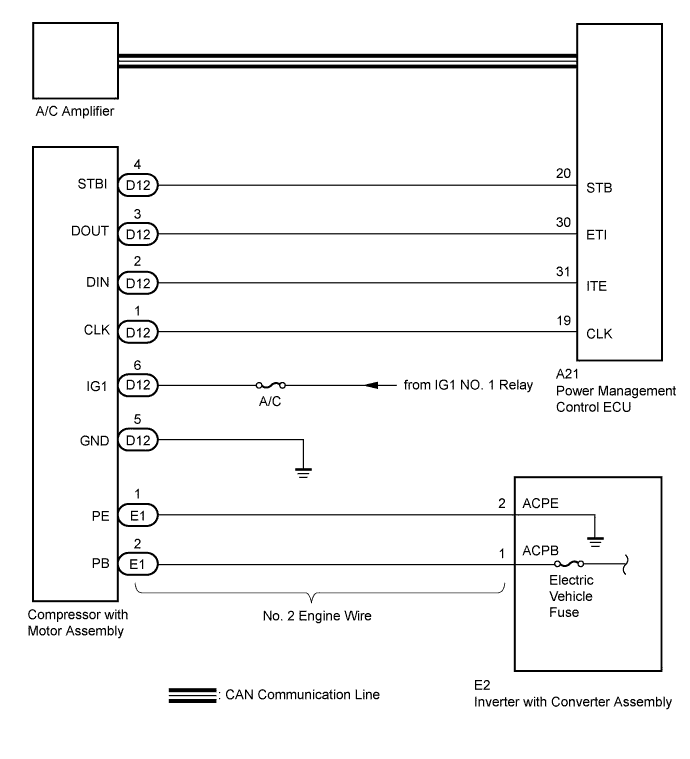

DTC P0AA6-611 Hybrid Battery Voltage System Isolation Fault |

| DTC No. | DTC Detection Condition | Trouble Area |

| P0AA6-611 | High voltage system insulation malfunction |

|

| 1.CHECK CAN COMMUNICATION SYSTEM |

Using the intelligent tester to check if the CAN communication system is functioning normally.

| Result | Proceed to |

| CAN DTC is not output | A |

| CAN DTC is output | B |

|

| ||||

| A | |

| 2.INSPECT COMPRESSOR WITH MOTOR ASSEMBLY |

Clear the DTCs (Click here).

Turn the power switch on (IG).

Prepare the vehicle according to the table below for 3 minutes.

| Item | Condition |

| Blower speed | HI |

| Temperature setting | MAX COLD |

| A/C | ON |

Turn the power switch off.

Remove the service plug grip.

|

Disconnect the connector from the compressor with motor assembly.

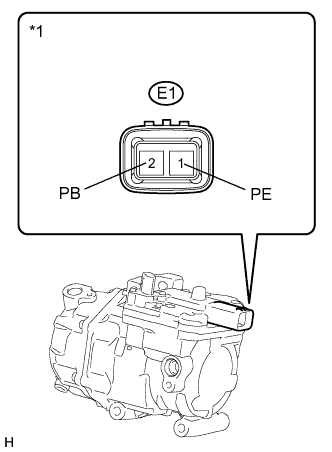

Using a megohmmeter, measure the resistance according to the value(s) in the table below.

| Tester Connection | Condition | Specified Condition |

| E1-1 (PE) - Body ground | Always | 2 MΩ or higher |

| E1-2 (PB) - Body ground | Always | 2 MΩ or higher |

| *1 | Component without harness connected (Compressor with Motor Assembly) |

|

| ||||

| OK | |

| 3.INSPECT AIR CONDITIONING CYCLE |

Reconnect the connector to the compressor with motor assembly.

Install the service plug grip.

Turn the power switch on (IG).

Set the A/C setting temperature to 25°C (77°F) and the blower switch LO and then operate the compressor for 10 minutes to circulate the refrigerant cycle with refrigerant and collect as much compressor oil as possible.

Turn the power switch off.

Using a spot cooler or other tools, cool down the compressor with motor assembly for 30 minutes, or leave the vehicle overnight before inspection.

Remove the service plug grip.

|

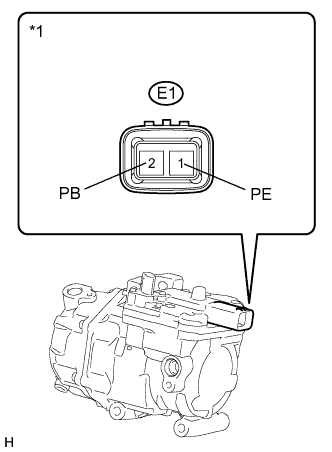

Disconnect the connector from the compressor with motor assembly.

Using a megohmmeter, measure the resistance according to the value(s) in the table below.

| Tester Connection | Condition | Specified Condition |

| E1-1 (PE) - Body ground | Always | 3 MΩ or higher |

| E1-2 (PB) - Body ground | Always | 3 MΩ or higher |

| *1 | Component without harness connected (Compressor with Motor Assembly) |

|

| ||||

| OK | ||

| ||