DTC P0A09-265 DC / DC Converter Status Circuit Low Input |

| DTC No. | INF Code | DTC Detection Condition | Trouble Area |

| P0A09 | 265 | Open or GND short in NODD signal circuit of DC/DC converter |

|

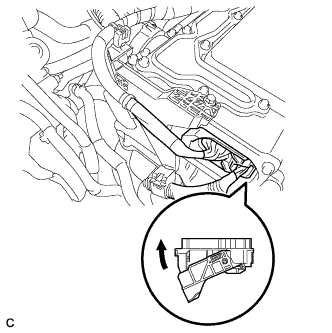

| 1.CHECK CONNECTOR CONNECTION CONDITION (INVERTER WITH CONVERTER ASSEMBLY CONNECTOR) |

|

Check that the service plug grip is not installed.

Check the connection of the low voltage connector of the inverter with converter assembly.

|

| ||||

| OK | |

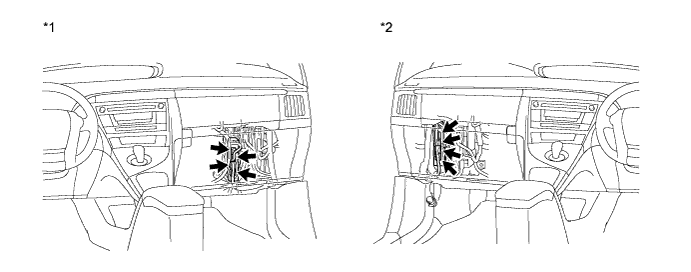

| 2.CHECK CONNECTOR CONNECTION CONDITION (POWER MANAGEMENT CONTROL ECU CONNECTOR) |

Check the connections of the power management control ECU connectors.

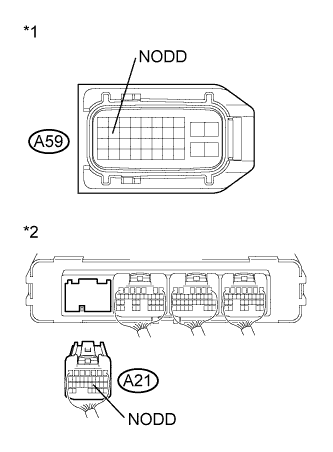

| *1 | for LHD | *2 | for RHD |

|

| ||||

| OK | |

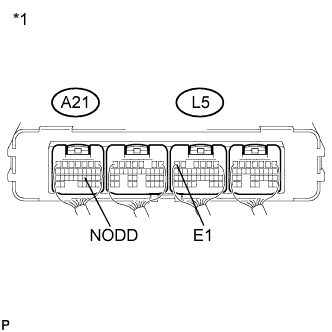

| 3.CHECK POWER MANAGEMENT CONTROL ECU (NODD) |

Turn the power switch on (READY).

|

Measure the voltage according to the value(s) in the table below.

| Tester Connection | Switch Condition | Specified Condition |

| A21-21 (NODD) - L5-6 (E1) | Power switch on (READY) | 5 to 7 V |

| *1 | Component with harness connected (Power Management Control ECU) |

Turn the power switch off.

|

| ||||

| OK | |

| 4.CLEAR DTC |

Connect the intelligent tester to the DLC3.

Turn the power switch on (IG).

Enter the following menus: Powertrain / Hybrid Control / Trouble Codes.

Clear DTCs and freeze frame data.

| NEXT | |

| 5.CHECK DTC OUTPUT (HV) |

Turn the power switch on (READY).

Enter the following menus: Powertrain / Hybrid Control / Trouble Codes.

Check if DTCs are output.

| Result | Proceed to |

| DTC P0A09-265 is not output. | A |

| DTC P0A09-265 is output again. | B |

Turn the power switch off.

|

| ||||

| A | |

| 6.CHECK FOR INTERMITTENT PROBLEMS |

Check for intermittent problems (Click here).

|

| ||||

| OK | ||

| ||

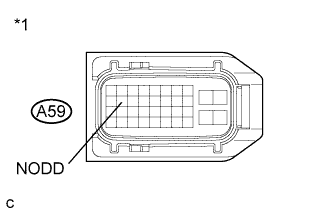

| 7.CHECK POWER MANAGEMENT CONTROL ECU |

Check that the service plug grip is not installed.

Disconnect connector A59 from the inverter with converter assembly.

|

Measure the resistance according to the value(s) in the table below.

| Tester Connection | Switch Condition | Specified Condition |

| A59-12 (NODD) - Body ground | Power switch off | 110 to 150 kΩ |

| *1 | Front view of wire harness connector (to Inverter with Converter Assembly) |

Connect the inverter with converter assembly connector.

|

| ||||

| OK | ||

| ||

| 8.CHECK HARNESS AND CONNECTOR (INVERTER WITH CONVERTER - POWER MANAGEMENT CONTROL ECU) |

Check that the service plug grip is not installed.

Disconnect connector A59 from the inverter with converter assembly.

Disconnect connector A21 from the power management control ECU.

|

Measure the resistance according to the value(s) in the table below.

| Tester Connection | Switch Condition | Specified Condition |

| A59-12 (NODD) - A21-21 (NODD) | Power switch off | Below 1 Ω |

| A59-12 (NODD) or A21-21 (NODD) - Body ground and other terminals | Power switch off | 10 kΩ or higher |

| *1 | Front view of wire harness connector (to Inverter with Converter Assembly) |

| *2 | Rear view of wire harness connector (to Power Management Control ECU) |

Connect the inverter with converter assembly connector.

Connect the power management control ECU connector.

|

| ||||

| OK | ||

| ||