DTC P0C3E-628 DC / DC Converter Temperature Sensor "B" Range / Performance |

DTC P0C41-627 DC / DC Converter Temperature Sensor "B" Intermittent / Erratic |

| DTC No. | INF Code | DTC Detection Condition | Trouble Area |

| P0C3E | 628 | Boost converter temperature (lower) calculated by the power management control ECU is different from the actual temperature for 10 seconds or more, and the boost converter temperature (lower) is too high. (1 trip detection logic) |

|

| P0C41 | 627 | Unusual sudden change in boost converter temperature sensor (lower) output occurs and the offset continues, or unusual sudden change in boost converter temperature sensor (lower) output occurs repeatedly. (1 trip detection logic) |

| 1.CHECK DTC OUTPUT (HV) |

Connect the intelligent tester to the DLC3.

Turn the power switch on (IG).

Enter the following menus: Powertrain / Hybrid Control / Trouble Codes.

Check if DTCs are output.

| Result | Proceed to |

| P0C3E-628 or P0C41-627 is output | A |

| Any of the following DTCs are also output. | B |

| DTC No. | Relevant Diagnosis |

| P0A93-346 | Inverter Cooling System Performance |

| P0C73-776 | Motor Electronics Coolant Pump "A" Control Performance |

| P314A-828 | Inverter Coolant Pump Speed Signal |

Turn the power switch off.

|

| ||||

| A | |

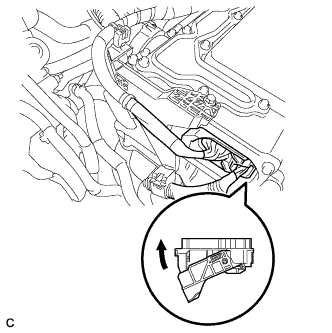

| 2.CHECK CONNECTOR CONNECTION CONDITION (INVERTER WITH CONVERTER ASSEMBLY CONNECTOR) |

|

Check that the service plug grip is not installed.

Check the connection of the low voltage connector of the inverter with converter assembly.

|

| ||||

| OK | |

| 3.CHECK QUANTITY OF HV COOLANT |

Check the coolant level in the inverter reserve tank.

Check for coolant leaks.

| Result | Proceed to |

| No leaks are found and coolant level in the inverter reserve tank assembly is above the low line. | A |

| No leaks are found and coolant level in the inverter reserve tank assembly is below the low line. | B |

| Coolant leaks are evident. | C |

|

| ||||

|

| ||||

| A | |

| 4.CHECK COOLANT HOSE |

Check if the hoses of the cooling system are kinked or clogged.

|

| ||||

| OK | |

| 5.PERFORM ACTIVE TEST USING INTELLIGENT TESTER (CONTROL THE ELECTRIC COOLING FAN) |

Connect the intelligent tester to the DLC3.

Turn the power switch on (IG).

Enter the following menus: Powertrain / Hybrid Control / Trouble Codes.

Clear DTCs and freeze frame data.

Enter the following menus: Powertrain / Engine and ECT / Active Test / Control the Electric Cooling Fan.

Perform the "Control the Electric Cooling Fan" Active Test.

Turn the power switch off.

|

| ||||

| OK | |

| 6.CHECK HV COOLANT (CHECK FOR CONDITIONS THAT MAY HAVE CAUSED FREEZING) |

Connect the intelligent tester to the DLC3.

Turn the power switch on (IG).

Read the freeze frame data Ambient Temperature using the intelligent tester.

Check if the freeze frame data Ambient Temperature is below freezing.

| Result | Proceed to |

| Ambient Temperature value is below freezing temperature of the HV coolant | A |

| Ambient Temperature value is above freezing temperature of the HV coolant | B |

Turn the power switch off.

|

| ||||

| A | |

| 7.REPLACE HV COOLANT |

Replace the HV coolant with coolant having an appropriate concentration (appropriate freeze point) for the vehicle usage conditions (Click here).

| NEXT | ||

| ||