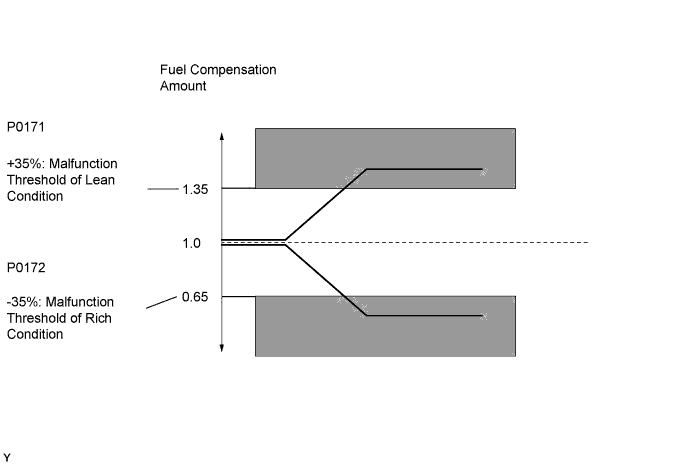

DTC P0171 System Too Lean (Bank 1) |

DTC P0172 System Too Rich (Bank 1) |

| DTC No. | DTC Detection Condition | Trouble Area |

| P0171 | With warm engine and stable air fuel ratio feedback, fuel trim considerably in error to lean side (2 trip detection logic) |

|

| P0172 | With warm engine and stable air fuel ratio feedback, fuel trim considerably in error to rich side (2 trip detection logic) |

|

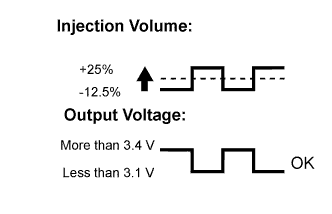

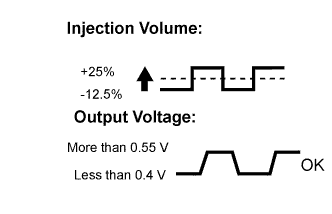

| Tester Display (Sensor) | Injection Volume | Status | Voltage |

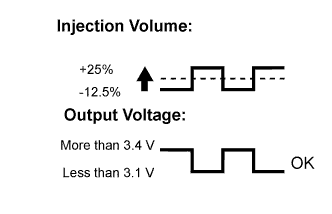

| AFS Voltage B1S1 (Air fuel ratio) | +25% | Rich | Less than 3.1 V |

| AFS Voltage B1S1 (Air fuel ratio) | -12.5% | Lean | More than 3.4 V |

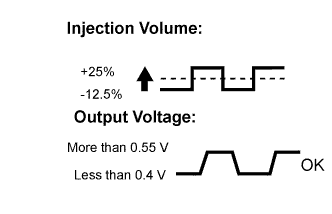

| O2S B1S2 (Heated oxygen) | +25% | Rich | More than 0.55 V |

| O2S B1S2 (Heated oxygen) | -12.5% | Lean | Less than 0.4 V |

| Case | Air Fuel Ratio Sensor (Sensor 1) Output Voltage | Heated Oxygen Sensor (Sensor 2) Output Voltage | Main Suspected Trouble Area |

| 1 |  |  | - |

| 2 |  |  |

|

| 3 |  |  |

|

| 4 |  |  |

|

| 1.CHECK ANY OTHER DTCS OUTPUT (IN ADDITION TO DTC P0171 OR P0172) |

Connect the intelligent tester to the DLC3.

Turn the power switch on (IG).

Turn the tester on.

Enter the following menus: Powertrain / Engine and ECT / DTC.

Read the DTCs.

| Result | Proceed to |

| DTC P0171 or P0172 is output | A |

| DTC P0171 or P0172 and other DTCs are output | B |

|

| ||||

| A | |

| 2.CHECK PCV HOSE CONNECTIONS |

Inspect the PCV hose connections (Click here).

|

| ||||

| OK | |

| 3.CHECK INTAKE SYSTEM |

Check the intake system for vacuum leaks (Click here).

|

| ||||

| OK | |

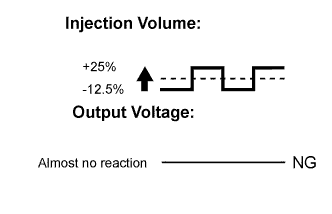

| 4.PERFORM ACTIVE TEST USING INTELLIGENT TESTER (AIR FUEL RATIO CONTROL) |

Connect the intelligent tester to the DLC3.

Turn the power switch on (IG) and turn the tester on.

Put the engine in inspection mode (Click here).

Start the engine.

Warm up the engine at an engine speed of 2500 rpm for approximately 90 seconds.

Enter the following menus: Powertrain / Engine and ECT / Active Test / Control the Injection Volume for A/F Sensor.

Perform the Control the Injection Volume for A/F Sensor operation with the engine idling (press the RIGHT or LEFT button to change the fuel injection volume).

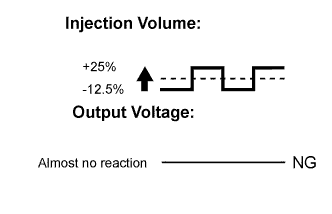

Monitor the voltage outputs of the air fuel ratio sensor and the heated oxygen sensor (AFS Voltage B1S1 and O2S B1S2) displayed on the intelligent tester.

| Tester Display (Sensor) | Injection Volume | Status | Voltage |

| AFS Voltage B1S1 (air fuel ratio) | +25% | Rich | Less than 3.1 V |

| -12.5% | Lean | More than 3.4 V | |

| O2S B1S2 (heated oxygen) | +25% | Rich | More than 0.55 V |

| -12.5% | Lean | Less than 0.4 V |

| Status AFS Voltage B1S1 | Status O2S B1S2 | Air Fuel Ratio Condition and Air Fuel Ratio Sensor Condition | Misfire | Suspected Trouble Area | Proceed to |

| Lean/Rich | Lean/Rich | Normal | - | - | C |

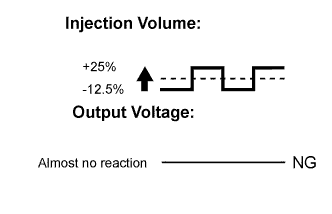

| Lean | Lean | Actual air fuel ratio lean | May occur |

| A |

| Rich | Rich | Actual air fuel ratio rich | - |

| |

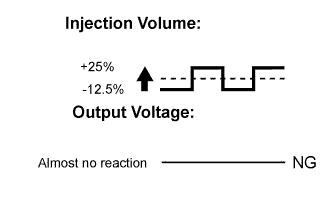

| Lean | Lean/Rich | Air fuel ratio sensor malfunction | - | Air fuel ratio sensor | B |

| Rich | Lean/Rich | Air fuel ratio sensor malfunction | - | Air fuel ratio sensor |

|

| ||||

|

| ||||

| A | |

| 5.READ VALUE USING INTELLIGENT TESTER (COOLANT TEMP) |

Connect the intelligent tester to the DLC3.

Turn the power switch on (IG).

Turn the tester on.

Enter the following menus: Powertrain / Engine and ECT / Data List / Coolant Temp.

Read the Data List twice, when the engine is both cold and warmed up.

|

| ||||

| OK | |

| 6.INSPECT MASS AIR FLOW METER SUB-ASSEMBLY |

Inspect the mass air flow meter sub-assembly (Click here).

|

| ||||

| OK | |

| 7.CHECK FUEL PRESSURE |

Check the fuel pressure (Click here).

|

| ||||

| OK | |

| 8.INSPECT FOR EXHAUST GAS LEAK |

Inspect for exhaust gas leaks from the exhaust manifold sub-assembly and exhaust pipes.

|

| ||||

| OK | |

| 9.CHECK SPARK AND IGNITION |

|

| ||||

| OK | |

| 10.INSPECT FUEL INJECTOR ASSEMBLY (INJECTION AND VOLUME) |

| Result | Proceed to |

| NG | A |

| OK | B |

|

| ||||

| A | ||

| ||

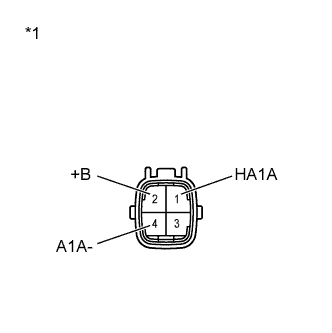

| 11.INSPECT AIR FUEL RATIO SENSOR NO.2 (HEATER RESISTANCE) |

|

Disconnect the air fuel ratio sensor connector.

Measure the resistance according to the value(s) in the table below.

| Tester Connection | Condition | Specified Condition |

| 1 (HA1A) - 2 (+B) | 20°C (68°F) | 1.8 to 3.4 Ω |

| 1 (HA1A) - 4 (A1A-) | Always | 10 kΩ or higher |

| *1 | Component without harness connected (to Air Fuel Ratio Sensor) |

Reconnect the air fuel ratio sensor connector.

|

| ||||

| OK | |

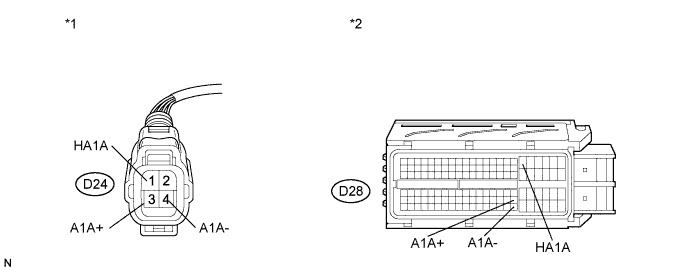

| 12.CHECK TERMINAL VOLTAGE (POWER SOURCE OF AIR FUEL RATIO SENSOR) |

|

Disconnect the air fuel ratio sensor connector.

Turn the power switch on (IG).

Measure the voltage according to the value(s) in the table below.

| Tester Connection | Switch Condition | Specified Condition |

| D24-2 (+B) - Body ground | Power switch on (IG) | 11 to 14 V |

| *1 | Front view of wire harness connector (to Air Fuel Ratio Sensor) |

Reconnect the air fuel ratio sensor connector.

|

| ||||

| OK | |

| 13.CHECK HARNESS AND CONNECTOR (AIR FUEL RATIO SENSOR - ECM) |

Disconnect the air fuel ratio sensor connector.

Disconnect the ECM connector.

Measure the resistance according to the value(s) in the table below.

| Tester Connection | Condition | Specified Condition |

| D24-1 (HA1A) - D28-18 (HA1A) | Always | Below 1 Ω |

| D24-3 (A1A+) - D28-103 (A1A+) | Always | Below 1 Ω |

| D24-4 (A1A-) - D28-126 (A1A-) | Always | Below 1 Ω |

| Tester Connection | Condition | Specified Condition |

| D24-1 (HA1A) or D28-18 (HA1A) - Body ground | Always | 10 kΩ or higher |

| D24-3 (A1A+) or D28-103 (A1A+) - Body ground | Always | 10 kΩ or higher |

| D24-4 (A1A-) or D28-126 (A1A-) - Body ground | Always | 10 kΩ or higher |

| *1 | Front view of wire harness connector (to Air Fuel Ratio Sensor) | *2 | Front view of wire harness connector (to ECM) |

Reconnect the air fuel ratio sensor connector.

Reconnect the ECM connector.

|

| ||||

| OK | |

| 14.REPLACE AIR FUEL RATIO SENSOR NO.2 |

Replace the air fuel ratio sensor (Click here).

| NEXT | |

| 15.PERFORM CONFIRMATION DRIVING PATTERN |

Connect the intelligent tester to the DLC3.

Turn the power switch on (IG).

Turn the tester on.

Clear the DTCs (Click here).

Turn the power switch off and wait for 30 seconds.

Turn the power switch on (IG) and turn the tester on.

Put the engine in inspection mode (Click here).

Start the power and warm it up.

With the engine warmed up, idle the engine for 2 minutes or more.

Drive the vehicle at between 75 and 120 km/h (45 and 75 mph) and at an engine speed of between 1400 and 3200 rpm for 5 minutes or more.

Enter the following menus: Powertrain / Engine and ECT / Utility / All Readiness.

Input the DTC: P0171, P0172.

Check the DTC judgment result.

| Result | Proceed to |

| ABNORMAL (DTC P0171 or P0172 is output) | A |

| NORMAL (DTC is not output) | B |

|

| ||||

| A | |

| 16.PERFORM ACTIVE TEST USING INTELLIGENT TESTER (CONTROL THE EGR STEP POSITION) |

Connect the intelligent tester to the DLC3.

Turn the power switch on (IG).

Turn the tester on.

Put the engine in inspection mode (Click here).

Start the engine and warm it up until the engine coolant temperature reaches 75°C (167°F) or more.

Enter the following menus: Powertrain / Engine and ECT / Active Test / Control the EGR Step Position.

Confirm the Throttle Idle Position is ON and check the engine idling condition and MAP values in the Data List while performing the Active Test.

| - | EGR Step Position (Active Test) | |

| 0 Steps | 0 to 30 Steps | |

| Idling condition | Steady idling | Idling changes from steady to rough idling |

| MAP (Data List) | MAP value is 20 to 40 kPa (150 to 300 mmHg) (EGR valve is fully closed) | MAP value is at least +10 kPa (75 mmHg) higher than when EGR valve is fully closed |

| Result | Proceed to |

| Outside of standard range | A |

| Within standard range | B |

|

| ||||

| A | |

| 17.INSPECT EGR VALVE ASSEMBLY |

Remove the EGR valve assembly (Click here).

Check if the EGR valve is stuck open.

Reinstall the EGR valve assembly (Click here).

|

| ||||

| OK | |

| 18.REPLACE ECM |

Replace the ECM (Click here).

| NEXT | |

| 19.CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED |

Connect the intelligent tester to the DLC3.

Turn the power switch on (IG).

Turn the tester on.

Clear the DTC (Click here).

Turn the power switch off and wait for 30 seconds.

Turn the power switch on (IG) and turn the tester on.

Put the engine in inspection mode (Click here).

Start the engine and warm it up.

With the engine warmed up, idle the engine for 2 minutes or more.

Drive the vehicle at between 75 and 120 km/h (45 and 75 mph) and at an engine speed of between 1400 and 3200 rpm for 5 minutes or more.

Enter the following menus: Powertrain / Engine and ECT / Utility / All Readiness.

Input the DTCs: P0171, P0172.

Check the DTCs judgment result.

| NEXT | ||

| ||