DTC P0102 Mass or Volume Air Flow Circuit Low Input |

DTC P0103 Mass or Volume Air Flow Circuit High Input |

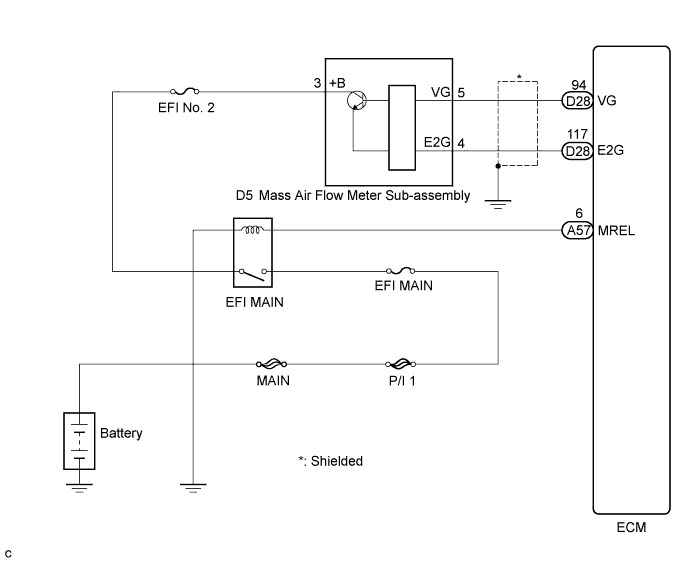

| DTC No. | DTC Detection Condition | Trouble Area |

| P0102 | Mass air flow meter voltage less than 0.2 V for 3 seconds (1 trip detection logic) |

|

| P0103 | Mass air flow meter voltage more than 4.9 V for 3 seconds (1 trip detection logic) |

|

| Mass Air Flow Rate (gm/sec) | Malfunction |

| Approximately 0.0 |

|

| 271.0 or more | Open in E2G circuit |

| 1.READ DTC OUTPUT |

Connect the intelligent tester to the DLC3.

Turn the power switch on (IG).

Turn the tester on.

Enter the following menus: Powertrain / Engine and ECT / DTC.

Read the DTCs.

| Result | Proceed to |

| DTC P0102 is output | A |

| DTC P0103 is output | B |

|

| ||||

| A | |

| 2.INSPECT MASS AIR FLOW METER SUB-ASSEMBLY (POWER SOURCE VOLTAGE) |

|

Disconnect the mass air flow meter sub-assembly connector.

Turn the power switch on (IG).

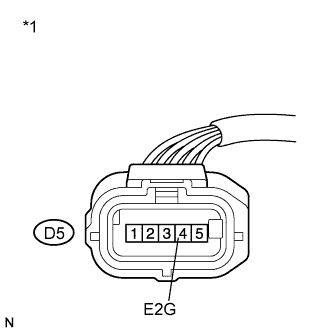

Measure the voltage according to the value(s) in the table below.

| Tester Connection | Switch Condition | Specified Condition |

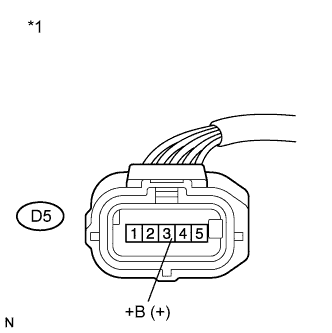

| D5-3 (+B) - Body ground | Power switch on (IG) | 11 to 14 V |

| *1 | Front view of wire harness connector (to Mass Air Flow Meter Sub-assembly) |

Reconnect the mass air flow meter sub-assembly connector.

|

| ||||

| OK | |

| 3.CHECK HARNESS AND CONNECTOR (MASS AIR FLOW METER SUB-ASSEMBLY - ECM) |

Disconnect the mass air flow meter sub-assembly connector.

Disconnect the ECM connector.

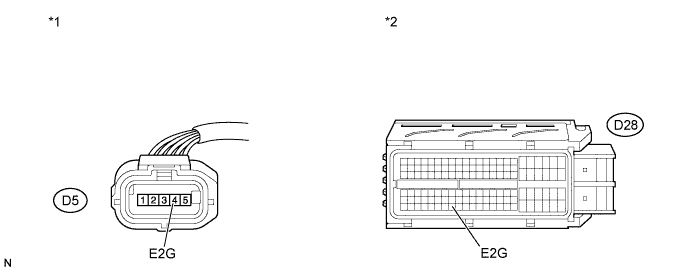

Measure the resistance according to the value(s) in the table below.

| Tester Connection | Condition | Specified Condition |

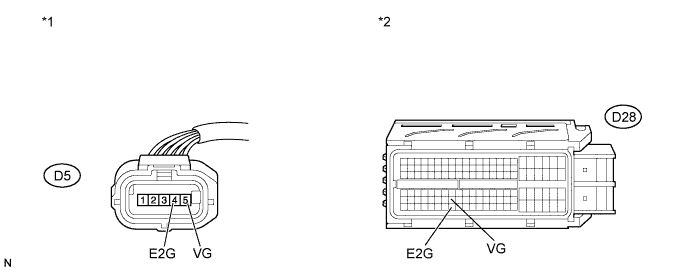

| D5-5 (VG) - D28-94 (VG) | Always | Below 1 Ω |

| D5-4 (E2G) - D28-117 (E2G) |

| Tester Connection | Condition | Specified Condition |

| D5-5 (VG) or D28-94 (VG) - Body ground | Always | 10 kΩ or higher |

| *1 | Front view of wire harness connector (to Mass Air Flow Meter Sub-assembly) | *2 | Front view of wire harness connector (to ECM) |

Reconnect the mass air flow meter sub-assembly connector.

Reconnect the ECM connector.

|

| ||||

| OK | |

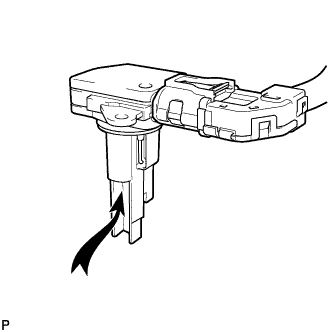

| 4.INSPECT MASS AIR FLOW METER SUB-ASSEMBLY |

|

Perform On-vehicle inspection (Click here).

Perform Inspection (Click here).

Inspect the function of the mass air flow meter sub-assembly.

Remove the mass air flow meter sub-assembly with the connector connected.

Connect the intelligent tester to the DLC3.

Turn the power switch on (IG).

Turn the tester on.

Enter the following menus: Powertrain / Engine and ECT / Data List / MAF.

Blow air to the mass air flow meter sub-assembly and check that the intake air amount reading changes.

|

| ||||

| OK | ||

| ||

| 5.CHECK HARNESS AND CONNECTOR (SENSOR GROUND) |

|

Disconnect the mass air flow meter meter sub-assembly connector.

Measure the resistance according to the value(s) in the table below.

| Tester Connection | Condition | Specified Condition |

| D5-4 (E2G) - Body ground | Always | Below 1 Ω |

| *1 | Front view of wire harness connector (to Mass Air Flow Meter Sub-assembly) |

Reconnect the mass air flow meter sub-assembly connector.

|

| ||||

| OK | ||

| ||

| 6.CHECK HARNESS AND CONNECTOR (MASS AIR FLOW METER SUB-ASSEMBLY - ECM) |

Disconnect the mass air flow meter sub-assembly connector.

Disconnect the ECM connector.

Measure the resistance according to the value(s) in the table below.

| Tester Connection | Condition | Specified Condition |

| D5-4 (E2G) - D28-117 (E2G) | Always | Below 1 Ω |

| *1 | Front view of wire harness connector (to Mass Air Flow Meter Sub-assembly) | *2 | Front view of wire harness connector (to ECM) |

Reconnect the mass air flow meter sub-assembly connector.

Reconnect the ECM connector.

|

| ||||

| OK | ||

| ||