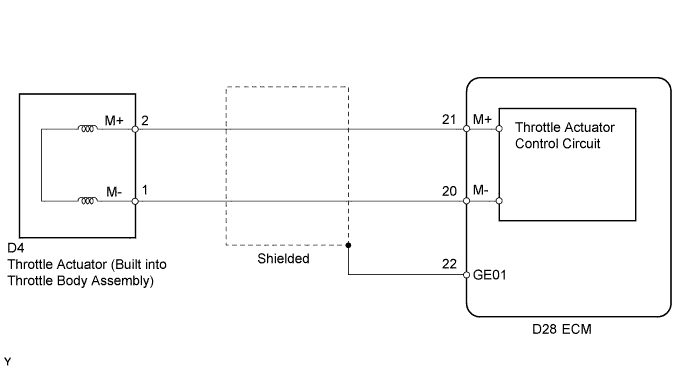

DTC P2102 Throttle Actuator Control Motor Circuit Low |

DTC P2103 Throttle Actuator Control Motor Circuit High |

| DTC No. | DTC Detection Condition | Trouble Area |

| P2102 | Both of the following conditions continue for 2 seconds (1 trip detection logic): (a) Throttle actuator duty ratio is 80% or more (b) Throttle actuator current is below 0.5 A |

|

| P2103 | Either condition is met (1 trip detection logic):

|

|

| 1.INSPECT THROTTLE BODY ASSEMBLY (RESISTANCE OF THROTTLE ACTUATOR) |

|

Disconnect the throttle body assembly connector.

Measure the resistance according to the value(s) in the table below.

| Tester Connection | Condition | Specified Condition |

| 2 (M+) - 1 (M-) | 20°C (68°F) | 0.3 to 100 Ω |

| *1 | Component without harness connected (Throttle Body Assembly) |

Reconnect the throttle body assembly connector.

|

| ||||

| OK | |

| 2.CHECK HARNESS AND CONNECTOR (THROTTLE BODY ASSEMBLY - ECM) |

Disconnect the throttle body assembly connector.

Disconnect the ECM connector.

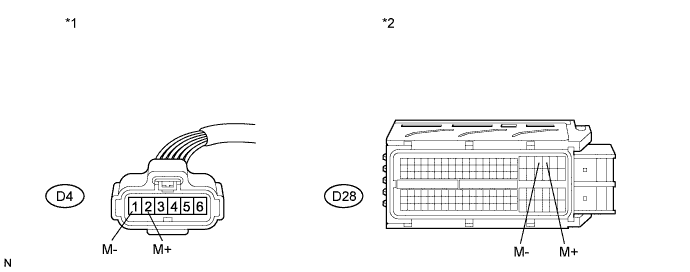

Measure the resistance according to the value(s) in the table below.

| Tester Connection | Condition | Specified Condition |

| D4-2 (M+) - D28-21 (M+) | Always | Below 1 Ω |

| D4-1 (M-) - D28-20 (M-) | Always | Below 1 Ω |

| Tester Connection | Condition | Specified Condition |

| D4-2 (M+) or D28-21 (M+) - Body ground | Always | 10 kΩ or higher |

| D4-1 (M-) or D28-20 (M-) - Body ground | Always | 10 kΩ or higher |

| *1 | Front view of wire harness connector (to Throttle Body Assembly) | *2 | Front view of wire harness connector (to ECM) |

Reconnect the ECM connector.

Reconnect the throttle body assembly connector.

|

| ||||

| OK | |

| 3.INSPECT THROTTLE BODY ASSEMBLY (VISUALLY CHECK THROTTLE VALVE) |

Check for foreign objects between the throttle valve and the housing.

|

| ||||

| OK | |

| 4.INSPECT THROTTLE BODY ASSEMBLY (THROTTLE VALVE) |

Check if the throttle valve opens and closes smoothly.

|

| ||||

| OK | ||

| ||