DTC P0112 Intake Air Temperature Circuit Low Input |

DTC P0113 Intake Air Temperature Circuit High Input |

| DTC No. | DTC Detection Condition | Trouble Area |

| P0112 | Short in intake air temperature sensor circuit for 0.5 seconds (1 trip detection logic) |

|

| P0113 | Open in intake air temperature sensor circuit for 0.5 seconds (1 trip detection logic) |

|

| Temperature Displayed | Malfunction |

| -40°C (-40°F) | Open circuit |

| 140°C (284°F) | Short circuit |

| 1.READ VALUE USING INTELLIGENT TESTER (INTAKE AIR) |

Connect the intelligent tester to the DLC3.

Turn the power switch on (IG).

Turn the tester on.

Enter the following menus: Powertrain / Engine and ECT / Data List / All Data / Intake Air.

Read the value displayed on the tester.

| Result | Proceed to |

| -40°C (-40°F) | A |

| 140°C (284°F) | B |

| Same as actual intake air temperature | C |

|

| ||||

|

| ||||

| A | |

| 2.READ VALUE USING INTELLIGENT TESTER (CHECK FOR OPEN IN WIRE HARNESS) |

Confirm good connection at the mass air flow meter sub-assembly.

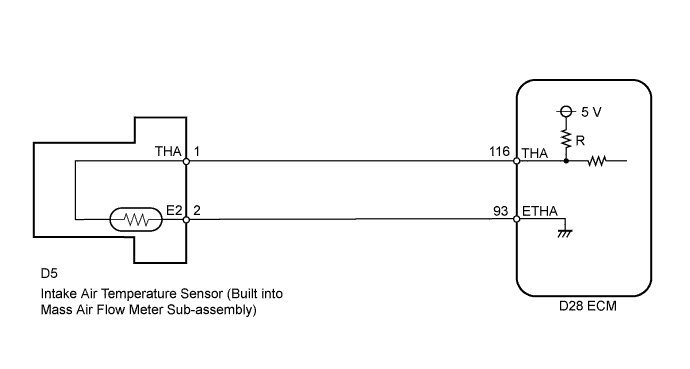

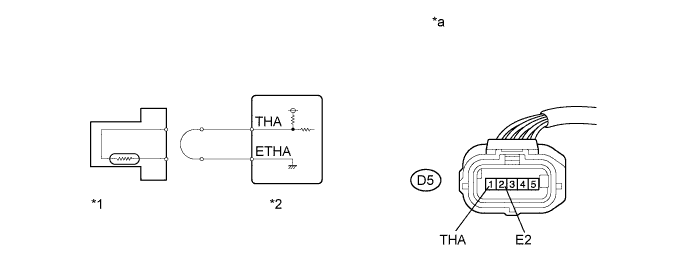

| *1 | Mass Air Flow Meter Sub-assembly | *2 | ECM |

| *a | Front view of wire harness connector (to Mass Air Flow Meter Sub-assembly) | - | - |

Disconnect the mass air flow meter sub-assembly connector.

Connect terminals 1 (THA) and 2 (E2) of the mass air flow meter sub-assembly connector on the wire harness side.

Connect the intelligent tester to the DLC3.

Turn the power switch on (IG).

Turn the tester on.

Enter the following menus: Powertrain / Engine and ECT / Data List / All Data / Intake Air.

Read the value displayed on the tester.

Reconnect the mass air flow meter sub-assembly connector.

|

| ||||

| OK | ||

| ||

| 3.CHECK HARNESS AND CONNECTOR (MASS AIR FLOW METER SUB-ASSEMBLY - ECM) |

Disconnect the mass air flow meter sub-assembly connector.

Disconnect the ECM connector.

Measure the resistance according to the value(s) in the table below.

| Tester Connection | Condition | Specified Condition |

| D5-1 (THA) - D28-116 (THA) | Always | Below 1 Ω |

| D5-2 (E2) - D28-93 (ETHA) | Always | Below 1 Ω |

Reconnect the mass air flow meter sub-assembly connector.

Reconnect the ECM connector.

|

| ||||

| OK | ||

| ||

| 4.READ VALUE USING INTELLIGENT TESTER (CHECK FOR SHORT IN WIRE HARNESS) |

|

Disconnect the mass air flow meter sub-assembly connector.

| *1 | Mass Air Flow Meter Sub-assembly |

| *2 | ECM |

Connect the intelligent tester to the DLC3.

Turn the power switch on (IG).

Turn the tester on.

Enter the following menus: Powertrain / Engine and ECT / Intake Air.

Read the value displayed on the tester.

Reconnect the mass air flow meter sub-assembly connector.

|

| ||||

| OK | ||

| ||

| 5.CHECK HARNESS AND CONNECTOR (MASS AIR FLOW METER SUB-ASSEMBLY - ECM) |

Disconnect the mass air flow meter sub-assembly connector.

Disconnect the ECM connector.

Measure the resistance according to the value(s) in the table below.

| Tester Connection | Condition | Specified Condition |

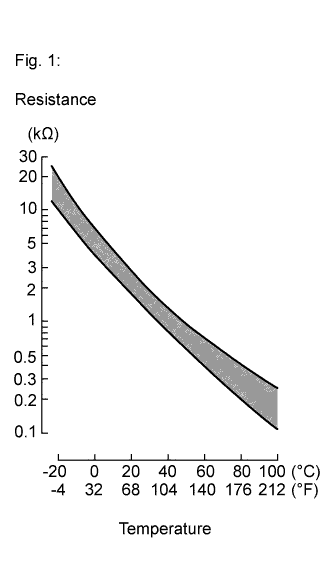

| D5-1 (THA) or D28-116 (THA) - Body ground | Always | 10 kΩ or higher |

Reconnect the mass air flow meter sub-assembly connector.

Reconnect the ECM connector.

|

| ||||

| OK | ||

| ||